Home > Product > DCS control system > DSAI130 57120001-P5 Logic input module

DSAI130 57120001-P5 Logic input module

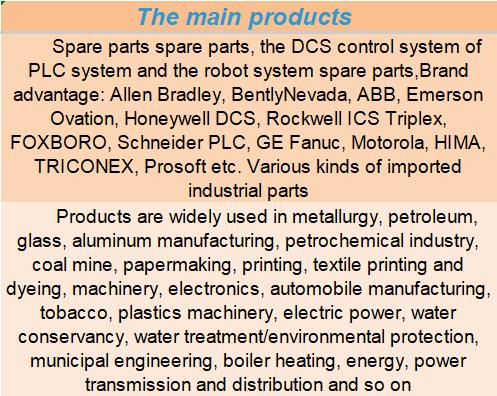

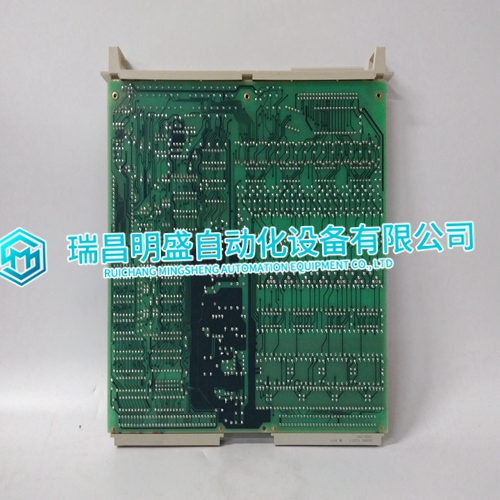

- Product ID: DSAI130 57120001-P5

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:DSAI13057120001-P5Logic input module

- Get the latest price:Click to consult

DSAI130 57120001-P5 Logic input module

Customers and third parties, who are not member states of the European Union, who are in control of the product at the end of its life or at the end of its use, are solely responsible for the proper disposal of the product. No person, firm, corporation, association or agency that is in control of product shall dispose of it in a manner that is in violation of any applicable federal, state, local or international law. Bently Nevada LLC is not responsible for the disposal of the product at the end of its life or at the end of its use.

Remote installation of the probe

wide operating parameters allow for in situ placement of the probe. Because a sample need not be brought to the analyzer, both the time lag and the potential for sample contamination associated with sample delivery systems are eliminated. This feature is extremely important in the measurement of very low moisture content or where rapid changes occur. When the integrity of the measurement is threatened by conductive or erosive particles, or adverse process conditions, sample conditioning will be required. GE manufactures turnkey sample-conditioning systems that maintain the integrity of the sample’s moisture content while removing the contaminants. These designs have been field-tested and have proven to be reliable, while requiring little or no maintenance.

Since the original design of the 3300 monitoring system

the Serial Data Interface/Dynamic Data Interface (SDI/DDI) communication protocols have been added. As a result, there are now three different 3300 configurations in the field: Original, Mixed, and SDI/DDI configurations. The purpose of this Compatibility Guide is to assist field personnel with the identification of each configuration and to explain the differences between these configurations. This document is not intended to be an upgrade guide to change from one configuration to another.