Home > Product > Servo control system > Bentley 3500/22M 138607-01 Transient Data Interface Module

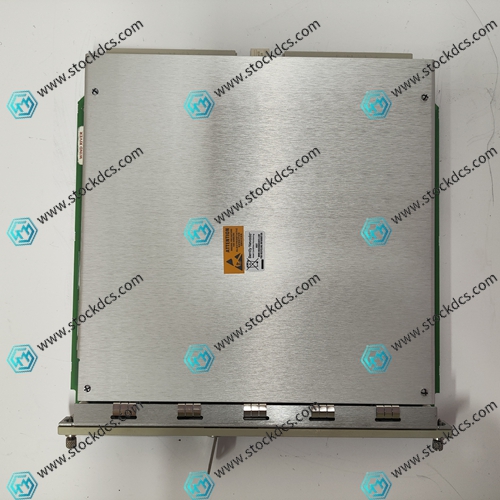

Bentley 3500/22M 138607-01 Transient Data Interface Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Bentley 3500/22M 138607-01 Transient Data Interface Module

Product Details Introduction

The Bently Nevada 3500/22M 138607-01 Transient Data Interface Module is one of the key components in the Bently Nevada 3500 series mechanical protection and condition monitoring system, specifically designed to collect and transmit transient events and dynamic data. The following are the main features, functions, and application areas of the transient data interface module:

Main features:

High performance data acquisition: designed to capture and process high-frequency transient events and dynamic data, providing accurate state monitoring.

Real time data transmission: It can transmit real-time data to the upper computer or data storage device, ensuring the timeliness and accuracy of the data.

Modular design: easy to integrate with other modules in the 3500 series, supporting flexible configuration and expansion.

Status indication: Equipped with LED indicator lights to display module status and activity, facilitating real-time monitoring and fault diagnosis.

Compatibility: Fully compatible with 3500 series systems, ensuring seamless integration and consistent system performance.

Function:

Transient event capture: Capture and record transient events that occur during the operation of rotating mechanical equipment, such as vibration, impact, and other dynamic signals.

Data transmission: Data is transmitted to the upper computer, data acquisition system, or remote monitoring system through standard communication interfaces for real-time analysis and storage.

Data processing: Real time processing of collected data, providing high-resolution and high-precision data output, supporting complex analysis and diagnosis.

System Integration: Seamless integration with other monitoring and protection modules in the 3500 series system, providing a comprehensive mechanical equipment monitoring solution.

Alarm and notification: Set alarm thresholds and conditions, and promptly issue alarm notifications when abnormal situations are detected to help prevent potential faults.

Application areas:

Power plant: Monitor and record transient events of power generation equipment such as turbines and generators to ensure safe operation and timely maintenance of the equipment.

Oil and gas: used for monitoring and protecting compressors, pumps, and other rotating equipment, detecting transient events to prevent equipment failures and production interruptions.

Chemical plant: Monitor the dynamic behavior of key equipment in the chemical production process to ensure process stability and product quality.

Metallurgy and mining: used to monitor transient events of large rotating machinery equipment, ensuring the safety and reliability of the equipment.

Offshore platforms: Monitor transient events of offshore oil platforms and drilling equipment to ensure the continuity and safety of offshore operations.

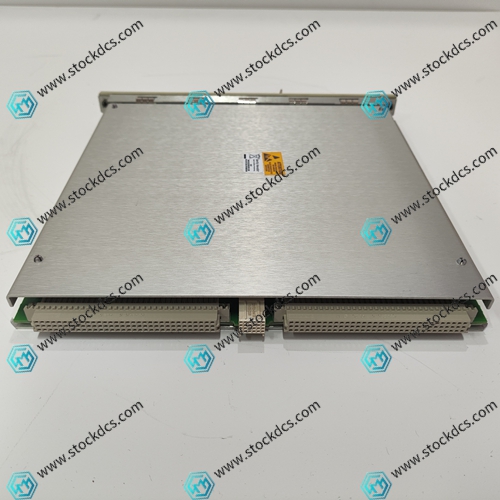

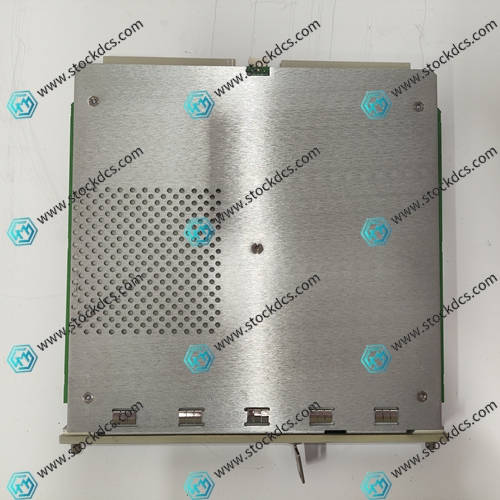

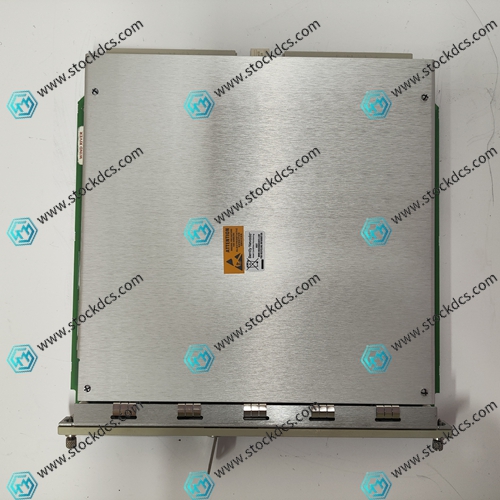

Product image

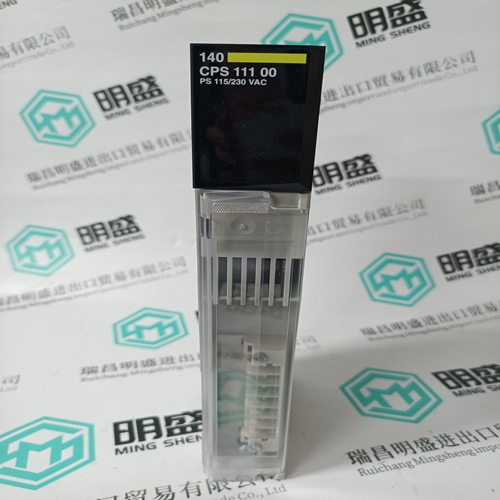

Related products:

ASEA E-31709 Robot Circuit Board

ASEA DSQC223 Robot Control Board

其他网站链接

| PMB33C-10114-00 | AMAT 0100-01341 | PXKB201 |

| PMB31B-10216-01 | AMAT 0090-A8211 | PXUB201 |

| PMB31B-20200-02 | AMAT 0100-00546 | SD821 |

| PMB33C-20116-03 | AMAT 0100-35083 | SD822 |

| PMB33F-00200-00 | AMAT 0090-A6200 | PFTL101A |

| PMB31B-10114-00 | AMAT 0100-76303 | PFTL201C |

| PMB31D-00200-01 | AMAT 0100-00061 | PFVL141V |

| PMB32D-00116-01 | AMAT 0100-00034 | PFVL141C |

| PMB31B-20201-03 | AMAT 0100-00429 | PFVL141R |

| PMB33E-10201-03 | AMAT 0500-00065 | PFVA401 |