Home > Product > DCS control system > LAM 810-520659-001 Semiconductor Control Module

LAM 810-520659-001 Semiconductor Control Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

LAM 810-520659-001 Semiconductor Control Module

Product Details Introduction

LAM 810-520659-001 is a control module used in semiconductor manufacturing equipment. This module is typically used to control and manage complex semiconductor manufacturing processes such as photolithography, etching, chemical vapor deposition (CVD), etc. The control module plays a crucial role in semiconductor manufacturing equipment, ensuring that the equipment can accurately execute complex process flows and provide high-precision and high reliability operations.

Main features and functions:

Precise control: This control module is capable of precise control of key parameters in the semiconductor manufacturing process, such as temperature, gas flow rate, pressure, current, voltage, etc., to ensure process stability and repeatability.

Real time monitoring: The module integrates real-time monitoring function, which can continuously monitor various parameters in the production process, ensure that the process conditions are within the preset range, and prevent abnormal situations from occurring.

High reliability: designed for long-term stable operation, suitable for harsh environmental conditions in semiconductor manufacturing processes, such as high temperatures, corrosive gases, and vacuum environments.

Modular design: Modular design facilitates integration into various semiconductor devices and is easy to maintain and upgrade, meeting constantly changing process requirements.

Data recording and analysis: Supports data recording function, which can capture and store key data in the process for subsequent analysis and optimization.

Communication Interface: Equipped with standard industrial communication interfaces such as Ethernet, RS-232/485, etc., for easy data exchange with the main control system or other devices.

Application areas:

Semiconductor manufacturing equipment: Various equipment widely used in the semiconductor manufacturing process, such as lithography machines, etching machines, CVD equipment, PVD equipment, etc., to ensure precise control of key process parameters.

Process development and optimization: During the semiconductor process development and optimization phase, it is used to precisely control experimental conditions and obtain data on the relationship between process parameters and equipment performance.

Equipment diagnosis and maintenance: Support self diagnostic function of equipment, monitor key parameters, warn potential problems in advance, and reduce equipment downtime.

Advantages:

High precision control: capable of meeting the extremely high requirements for parameter control in semiconductor manufacturing processes, ensuring product consistency and yield.

Strong adaptability: The design is suitable for various semiconductor manufacturing processes, flexible configuration, and meets the needs of different process conditions.

Long lifespan and low failure rate: With high reliability design, it is suitable for production environments with high load continuous operation, reducing equipment failure rate and maintenance costs.

Data driven optimization: Through data recording and analysis functions, help users optimize process parameters, improve production efficiency and product quality.

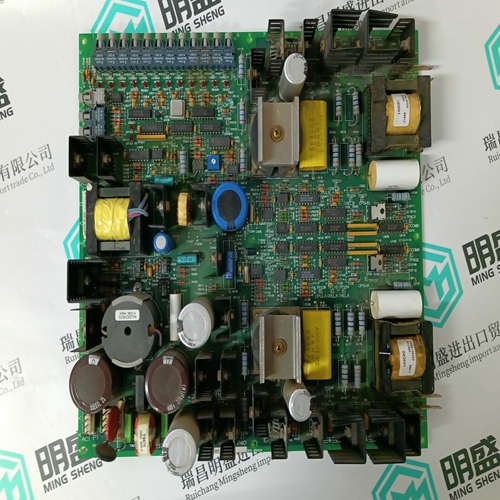

Product image

Related website links

ABB XXD129A01 Card Module Controller

AMAT 0190-66253 Communication Module

RADISYS 061-05927-0031 adapter module

Other website links

| PMB32D-00116-01 | AMAT 0100-00034 | PFVL141C |

| PMB31B-20201-03 | AMAT 0100-00429 | PFVL141R |

| PMB33E-10201-03 | AMAT 0500-00065 | PFVA401 |

| PMB31D-10100-00 | AMAT 0100-09362 | PFEA111 |

| PMB33C-00114-02 | AMAT 0100-00852 | PFEA113 |

| PMB33E-00101-01 | AMAT 0100-00025 | PFRL 101A |

| PMB31B-20101-01 | AMAT 0100-20265 | PFRL 101C |

| PMB31B-20114-03 | AMAT 0100-00015 | PFTL301E |

| PMB31B-00216-00 | AMAT 0100-03536 | PFCL301E |