Home > Product > DCS control system > REXROTH DKC01.3-012-3-MGP-01VRS servo controller

REXROTH DKC01.3-012-3-MGP-01VRS servo controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:DKC01.3-012-3-MGP-01VRS

- Get the latest price:Click to consult

REXROTH DKC01.3-012-3-MGP-01VRS servo controller

Product Details Introduction

Rexroth DKC01.3-012-3-MGP-01VRS is a servo controller produced by Bosch Rexroth, belonging to the IndraDrive series. This servo controller, when used in conjunction with Rexroth's servo motors, can achieve high-precision motion control. The following are the main features and application areas of the servo controller:

Main features:

Model: DKC01.3-012-3-MGP-01VRS

Series: DKC (IndraDrive)

Power output: 12A continuous current, maximum current is 36A

Input voltage: three-phase power supply, 380-480V AC

Communication interface: Supports multiple bus communication protocols such as Profibus DP, SERCOS, EtherCAT, CANopen, etc

Control mode: Supports speed control, position control, and torque control

Built in safety function: equipped with STO (Safety Torque Off) function, in compliance with international safety standards

Cooling method: natural cooling or forced air cooling to ensure efficient heat dissipation

Size: Compact design, easy to integrate into various control cabinets and equipment

Application areas:

The Rexroth DKC01.3-012-3-MGP-01VRS servo controller is widely used in industrial automation fields that require precise motion control. Its main application areas include:

1. CNC machine tools

Application: Used to control the feed axis, spindle, etc. of machine tools, ensuring high precision and dynamic performance of machining.

Advantages: Supports complex multi axis synchronous control, suitable for high-precision machining tasks.

2. Packaging Machinery

Application: Control various moving parts in packaging equipment, such as film rolling, cutting, sealing, etc.

Advantages: High speed response and precise control help improve the efficiency and product quality of the production line.

3. Printing Machinery

Application: Control key movements such as paper conveying and alignment of printing machines to ensure printing accuracy and consistency.

Advantage: Highly flexible control mode to meet the needs of different printing tasks.

4. Textile Machinery

Application: Used to control moving parts in textile equipment, such as weaving machines, spinning machines, etc.

Advantages: High precision and reliability ensure the stability of the textile process and product quality.

5. Material handling system

Application: In automated warehousing and logistics systems, control the movement of equipment such as conveyor belts and robotic arms.

Advantages: Fast response and precise positioning, improving the efficiency and accuracy of material handling.

6. Robots

Application: Used for motion control of various axes in industrial robots, ensuring the accuracy and coordination of robot actions.

Advantages: Supports complex motion trajectory control and is suitable for various automated operations.

7. Assembly line

Application: Control various movements on automated assembly lines, such as screw tightening, component alignment, etc.

Advantage: Precise control ensures consistency and quality of assembly.

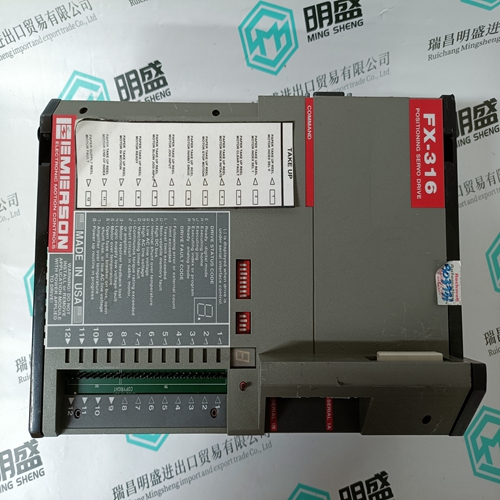

Product image

Related website links

HONEYWELL 05704-A-0146 Digital

PROSOFT MVI46-MCM communicatio

ABB 3DDE300417 Input/Output Board

Other website links

| PMA65R-11100-00 | AMAT 0100-76267 | PFTL101B 50KN |

| PMA54Q-11100-00 | Amat 0100-03499 | PFTL101BE |

| PMA53Q-00100-00 | AMAT 0100-20321 | PFTL101BE-2.0KN 3BSE004214R1 2.0KN |

| PMA55S-10100-00 | AMAT 0100-00005 | PFTL101BER |

| PMA55Q-10100-00 | AMAT 0100-00048 | PFTL101BER-2.0KN 3BSE023158R1 2.0KN |

| PMA55R-00100-00 | AMAT 0100-09153 | PFTL201C |

| PMA53R-00100-00 | AMAT 0100-09081 | PFTL201CE |