Home > Product > DCS control system > Rexroth CSH01.3C-ET-ENS-NNN-CCD-NN-S-NN-FW servo controller

Rexroth CSH01.3C-ET-ENS-NNN-CCD-NN-S-NN-FW servo controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Rexroth CSH01.3C-ET-ENS-NNN-CCD-NN-S-NN-FW servo controller

Product Details Introduction

The Rexroth CSH01.3C-ET-ENS-NNN-CCD-NN-S-NN-FW servo controller is a high-performance servo drive controller under Bosch Rexroth, widely used in various industrial automation fields. It has powerful functionality and flexible configuration, suitable for various applications that require precise control and high dynamic response. The following are the main application areas of this servo controller:

1. CNC machine tools

Application: Used to control the spindle and feed axis of CNC machine tools, achieving high-precision metal processing such as milling, turning, drilling, and grinding processes.

Advantages: Provides high dynamic response and precise control, ensuring machining accuracy and process stability.

2. Automated production line

Application: Control conveyor belts, robotic arms, sorting systems, etc. in automated production lines to achieve automated assembly, packaging, and processing.

Advantage: Supports multi axis synchronous control to ensure efficient operation and precise operation of the production line.

3. Robots

Application: Used to drive industrial robots, collaborative robots, etc., to achieve complex motion control tasks such as welding, spraying, handling, assembly, etc.

Advantages: Provides high precision and dynamic performance, suitable for complex and diverse robot application scenarios.

4. Packaging Machinery

Application: Control key components in packaging equipment, such as filling machines, labeling machines, sealing machines, etc., to ensure the precision and efficiency of the packaging process.

Advantages: Provides fast response time and precise positioning control, suitable for high-speed packaging production lines.

5. Printing Machinery

Application: Control paper transport, print head movement, etc. in printing machinery to ensure printing quality and production efficiency.

Advantage: Provides high-resolution motion control to meet the precision requirements during the printing process.

6. Textile Machinery

Application: Used for motion control in textile machinery, such as weaving machines, dyeing and finishing equipment, sewing machines, etc., to achieve precise weaving and processing.

Advantage: Provides stable high-speed operation to ensure consistency and quality in textile production.

7. Plastic and rubber processing equipment

Application: Control key moving parts of injection molding machines, extruders, and other equipment to ensure precise molding of plastic products.

Advantages: High dynamic performance and precise control, suitable for complex plastic processing techniques.

8. Food and beverage processing equipment

Application: Used in food and beverage production lines to control processes such as mixing, stirring, filling, labeling, etc., ensuring production efficiency and hygiene standards.

Advantages: High precision control and fast response, suitable for high demand environments in mass production.

9. Automated warehousing system

Application: Control stacker cranes, conveyors, sorting systems, etc. in automated warehousing systems to achieve efficient logistics management.

Advantages: Multi axis control and precise positioning ensure efficient and accurate warehousing operations.

10. Medical equipment

Application: Used for motion control in precision medical equipment, such as surgical robots, diagnostic equipment, laboratory automation equipment, etc.

Advantages: High precision and reliability ensure the safety and effectiveness of medical operations.

11. Energy equipment

Application: In the field of renewable energy such as wind power and solar equipment, control key moving parts and optimize energy conversion efficiency.

Advantages: Provides precise motion control and efficient management, supporting sustainable energy applications.

The Rexroth CSH01.3C-ET-ENS-NNN-CCD-NN-S-NN-FW servo controller plays a key role in many industrial fields due to its excellent performance, flexible configuration, and wide applicability, especially suitable for application scenarios that require high precision and high dynamic response.

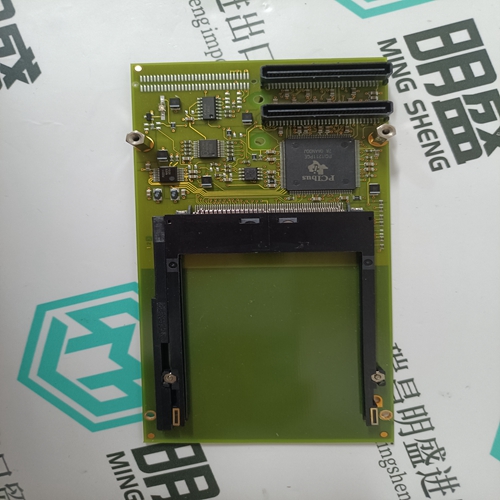

Product image

Related website links

ABB 3DDE300417 Input/Output Board

ABB XXD129A01 Card Module Controller

AMAT 0190-66253 Communication Module

Other website links

| PMB31D-10100-00 | AMAT 0100-09362 | PFEA111 |

| PMB33C-00114-02 | AMAT 0100-00852 | PFEA113 |

| PMB33E-00101-01 | AMAT 0100-00025 | PFRL 101A |

| PMB31B-20101-01 | AMAT 0100-20265 | PFRL 101C |

| PMB31B-20114-03 | AMAT 0100-00015 | PFTL301E |

| PMB31B-00216-00 | AMAT 0100-03536 | PFCL301E |