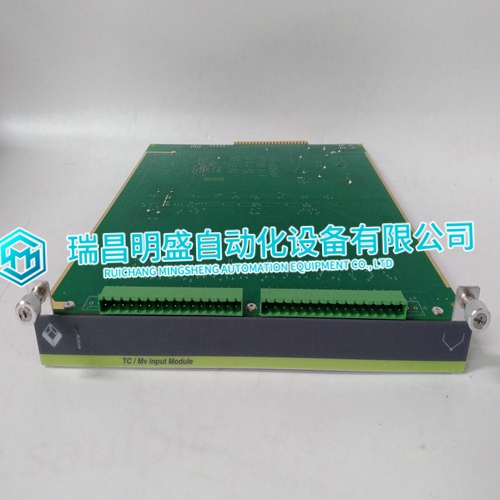

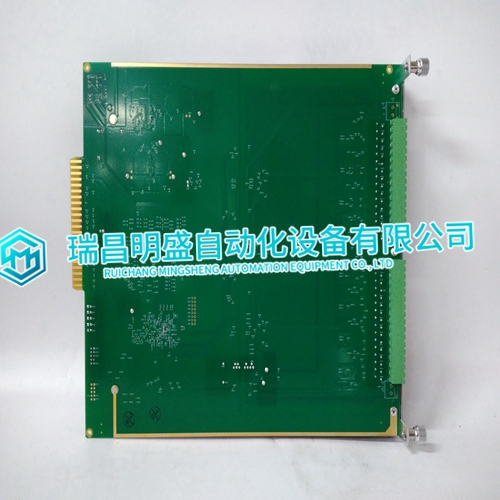

Home > Product > Robot control system > METSO IOP313 Pulse input module

METSO IOP313 Pulse input module

- Product ID: IOP313

- Brand: METSO

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:METSOIOP313Pulse input module

- Get the latest price:Click to consult

METSO IOP313 Pulse input module

Droop/Isochronous Load Sharing on an Isolated Bus Droop/Isochronous combines the first two modes. All generator sets in the system except one are operated in the droop mode. The one unit not in droop is operated in the isochronous mode. It is known as the swing machine. In this mode, the droop machines will run at the frequency of the isochronous unit. The droop and speed settings of each droop unit are adjusted so that each generates a fixed amount of power as illustrated in Figure 5-3. The output power of the swing machine will change to follow changes in the load demand.

Maximum load for this type of system

is limited to the combined output of the swing machine the total set power of the droop machines. The minimum system load cannot be allowed to decrease below the output set for the droop machines. If it does, the system frequency will change, and the swing machine can be motorized. The machine with the highest output capacity should be operated as the swing machine, so that the system will accept the largest load changes within its capacity.

Isochronous Load Sharing on an Isolated Bus

Isochronous Load Sharing is the most common means of paralleling multiple generators together to a common load on an isolated bus. The EGCP-2 uses Isochronous Load Sharing control when operating in a Multiple Unit mode with the Load Control Mode in either Normal or Soft Transfer. Isochronous load sharing operates all generator sets in a system in the isochronous mode. Load sharing is accomplished by using the load sensor of the EGCP-2 to bias the speed reference of the isochronous governor. The EGCP-2 load sensors are connected by inter-control RS-485 network. In the case of the EGCP-2 control, Isochronous Load Sharing is done digitally via this network. Any imbalance in load between units will cause a change to the regulating circuit in each governor. While each unit continues to run at isochronous speed, these changes force each machine to supply a proportional share of power to meet the total load demand on the system.