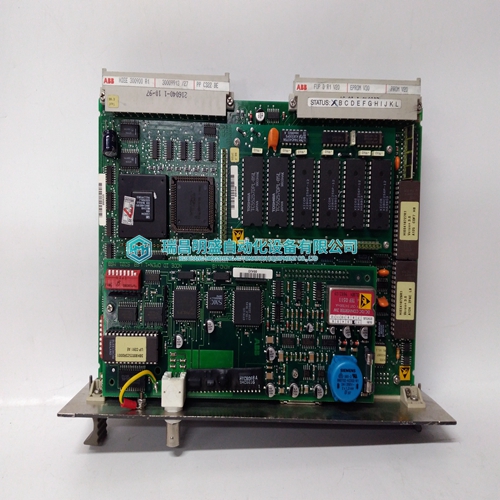

Home > Product > Gas turbine system > IS210AEDBH4AGD Gas turbine card

IS210AEDBH4AGD Gas turbine card

- Product ID: IS210AEDBH4AGD

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:IS210AEDBH4AGDGas turbine card

- Get the latest price:Click to consult

IS210AEDBH4AGD Gas turbine card

The Process Master EGCP-2 will not automatically pass the Master flag. When operating multiple units in Process control there are ways to pass the Master. To pass the Master to a slave unit, the slave unit must have the same discrete inputs (Auto, Run w/Load, and Process) as the Master.

1. Pass the Master by changing the priority of the slave to 1. The EGCP-2 will pass the Master to the slave, and if the new Master has the same process reference setting there will be no noticeable change.

2. Pass the Master by removing the Auto input from the present Master. This is the recommended way to pass the Master when the present Master receives a shutdown fault. An external device will have to recognize that the Master is shutdown and that there is another EGCP-2 that is available to be the Master. The generators will unload to their kW Load Low Limit settings, and as soon as the Master changes, the new Master will load the units until the Process reference setting is achieved.

The Process Master controls

the slave units by increasing or decreasing the System Load signal. The System Load is a 0 – 100% signal. If the Process Master receives a Hard Shutdown fault, it will open its breaker and shutdown. The slave units are now receiving a 0% System Load signal, and will operate at the kW Load Low Limit setting.The Process Reference point can be scaled in any one of 14 selectable Process Units. The Process Units selection can allow the operator to see the Process Reference value in kW or MW instead of milliamps. The Process Low and High Value will need to be configured whenever a different Process Unit is selected. The Process Unit will also change the Process Reference, Process Low Limit, and Process High Limit.

Additional features of the process control

are an adjustable process input signal filter and adjustable deadband on the integrator. The adjustable filter allows reducing bandwidth when controlling a noisy process such as experienced in digester gas fuel applications. The deadband is useful in noisy applications as well as for very slow processes. The process control function is configurable for direct and inverse action. Direct process control is where the sensed input signal increases as the load increases (such as where the sensed input is exhaust pressure or export power). An inverse action control is where the sensed input signal decreases as the load increases (such as when controlling import power where the import power will decrease as the generating system picks up more of the local load).