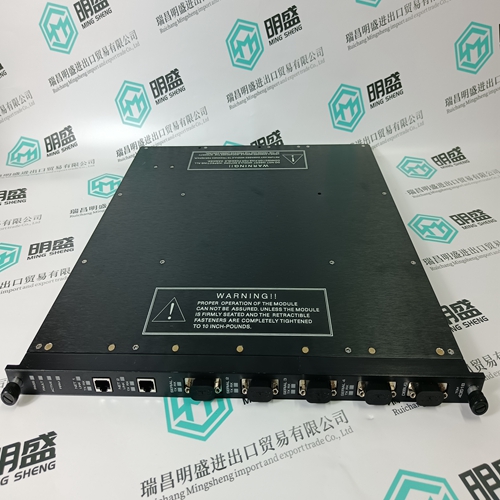

Home > Product > Gas turbine system > SD-98762 101-098762-001 processor

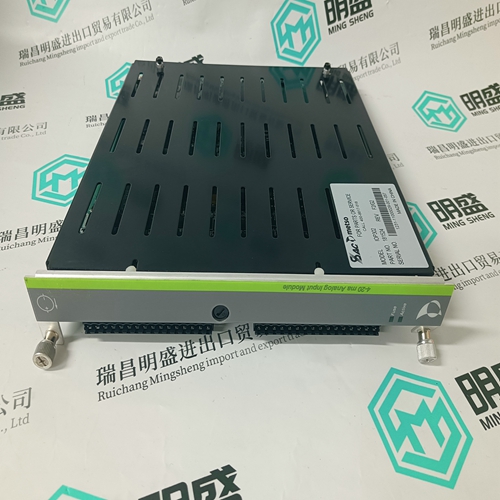

SD-98762 101-098762-001 processor

- Product ID: SD-98762 101-098762-001

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:SD-98762101-098762-001processor

- Get the latest price:Click to consult

SD-98762 101-098762-001 processor

A typical automatic sequencing scenario is shown below. The system represented is composed of three units on an isolated bus feeding varying plant loads that are fed by the generators. The master unit (network priority #1) has the following set points for sequencing in the Sequencing and Comms menu: Max Gen Load = 65% Next Genset Delay = 30 seconds Rated Load Delay = 5 seconds Max Start Time = 60 seconds Min Gen Load = 25% Reduced Gen Dly. = 30 seconds Max Stop Time = 15 seconds

These settings are for demonstration only. Sequencing set points may vary depending upon system requirements.

Auto Sequence Delay

The Auto Sequence Delay timer starts when the Master unit closes its generator breaker. This will delay the Master unit from sequencing off slave units until this timer has expired. Sequencing can be delayed for 20 minutes, allowing the system load to stabilize. The EGCP-2 uses calculated system load levels to determine the points at which the master sequences on or off units. The master may not sequence a unit off load, even though it is at or below the min gen load set point, if this would cause the system load to rise above the Max Gen Load minus 10%.

Point B

Master Generator responds to a step load that brings the system load to approximately 70%. This level exceeds the Max. Gen Load set point (65%) in the Sequence and Comms tuning menu. The Master control begins timing for the Next Genset Delay period 30 seconds. After the 30 seconds expires, the load is still above the Max Gen Load set point. The master control issues a start command to the next unit on (network priority #2).