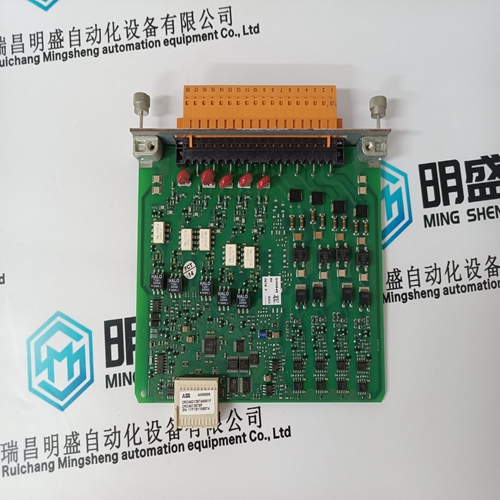

Home > Product > DCS control system > HONEYWELL CC-PAIH51 51410069-275 module

HONEYWELL CC-PAIH51 51410069-275 module

- Product ID: CC-PAIH51 51410069-275

- Brand: HONEYWELL

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:HONEYWELLCC-PAIH5151410069-275module

- Get the latest price:Click to consult

HONEYWELL CC-PAIH51 51410069-275 module

Sequence of Start-up and Checking Parameters

1. Enter program set points in all menus.

2. Check discrete inputs in I/O status menu.

3. Set crank repeats to 0.

4. Set synchronizer mode to check.

5. Set load control mode to normal.

6. Start engine using test switch (discrete input 2) of EGCP-2.

7. Check Engine Status screen for engine rpm readout confirm rpm is correct for unit.

8. Check voltage of unit in Generator Status screen—calibrate voltage if needed.

9. Adjust AVR voltage at AVR if needed to achieve rated generator voltage.

10. Follow AVR connection and setup procedure in Appendix C.

11. Check that voltage raise/lower switches (discrete inputs 4 and 5) operate properly. • Set voltage ramp time if needed.

12. Check that load raise/lower switches (discrete inputs 6 and 7) operate properly. • Set load raise/lower rates if needed. • Verify speed change with raise/lower load inputs.

13. Check mains voltage in synchroscope status menu (if available)—calibrate if needed.

14. Remove Test Input. Verify engine shuts down properl

Loading the Generator Set

WARNING—CT/PT PHASING Operation of the engine/generator set with incorrect CT and PT phasing could cause serious injury or damage to equipment. If the load on the unit rises rapidly when the generator or mains breaker is closed, immediately open the breaker and shut the unit down. Check the phasing of the PT and CTs. DO NOT permit the unit to continue to pick up load or operate the system without correcting this condition

After generator breaker closes to the mains

monitor Generator Status screen. a. Monitor kW load on unit. b. Monitor kVAR/PF on unit. 1. As set by reactive load control setting. Adjust load control gain, stability, and derivative for stable load control. Once satisfied with load control operation, switch to process control (if applicable). . Confirm ramp to process reference level. a. Tune process control for best response. Remove run with load input to unit. a. Verify unload ramping. b. Verify unload trip point. c. Verify generator breaker opens. d. Verify cooldown timer (if reached). Set crank repeats, base load reference, process reference, load ramp times, and load control mode as required for proper operation. This concludes the Mains Parallel Master Setup.