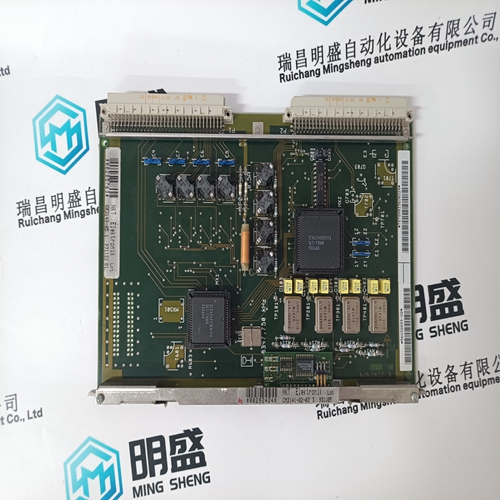

Home > Product > DCS control system > AI845 3BSE023675R1 control module

AI845 3BSE023675R1 control module

- Product ID: AI845 3BSE023675R1

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:AI845 3BSE023675R1control module

- Get the latest price:Click to consult

AI845 3BSE023675R1 control module

Personnel performing preventive maintenance should meet the following qualifications. • Maintenance personnel should be qualified electrical technicians or engineers that know the proper use of test equipment. • Maintenance personnel should be familiar with the IMASI13 module, module mounting unit, have experience working with process control systems, and know what precautions to take when working on live AC/DC systems.

Table 7-1 is the preventive maintenance schedule for the IMASI13 module. The table lists the preventive maintenance tasks in groups according to their specified maintenance interval. Instructions for tasks that require further explanation are covered under Preventive Maintenance Procedures. NOTE: The preventive maintenance schedule is for general purposes only. Your application may require special attention.

Equipment and Tools Required

The tools and equipment required for maintenance procedures are:

• Antistatic vacuum.

• Screwdriver (medium length).

• Isopropyl alcohol (99.5 percent electronic grade).

• Distilled water.

• Compressed air.

• Foam-tipped swabs.

• Lint-free cloths.

• Nonabrasive eraser.

Preventive Maintenance Procedures

This section covers tasks from Table 7-1 that require specific instructions or further explanation.

• Cleaning printed circuit boards and edge connectors.

• Checking signal, power and ground connections.

Never clean electrical parts or components with live power present. Doing so exposes you to an electrical shock hazard. Wear eye protection whenever working with cleaning solvents. When removing solvents from printed circuit boards using compressed air, injury to the eyes could result from splashing solvent as it is removed from the printed circuit board.