Home > Product > DCS control system > GE 201CI-1 Controller Module

GE 201CI-1 Controller Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

GE 201CI-1 Controller Module

Product Details Introduction

The GE 201CI-1 controller module is a controller module produced by General Electric (GE), widely used in the fields of industrial automation and process control. It is part of GE's PACSystems series of controllers, suitable for logical control and management tasks of complex systems.

Main functions and features:

High performance control: The GE 201CI-1 controller module uses a high-performance processor that can quickly handle complex logic and computational tasks, ensuring high efficiency and reliability in real-time control applications.

Multi input/output interface: Supports multiple digital and analog input/output (I/O) interfaces, allowing for flexible connection to various sensors, actuators, and peripheral devices on site.

Network communication: It integrates multiple industrial communication protocols, supports Ethernet, Modbus, Profinet and other protocols, facilitates data exchange with other control systems or upper level systems, and achieves distributed control.

Modular design: Modular structure, easy to expand and maintain, can add additional I/O modules or functional modules according to requirements, providing flexible system expansion capabilities.

High reliability: Industrial grade design, with good anti-interference ability and environmental adaptability, capable of long-term stable operation in harsh industrial environments. Support redundant power supply and communication to ensure system reliability.

Programming environment: Compatible with GE's Proficy Machine Edition and other programming software, supporting multiple programming languages such as Ladder Logic, Sequential Function Diagram (SFC), Structured Text (ST), etc., making it convenient for engineers to develop and debug logic.

Technical specifications:

Processor: 32-bit or 64 bit high-performance processor capable of processing large-scale data and complex logic.

Memory: Adequate RAM and flash memory are used to store programs and data.

I/O support: Supports multiple digital and analog I/O modules, and can be flexibly configured according to specific needs.

Communication interface: Integrated Ethernet, serial port and other interfaces, supporting multiple standard industrial communication protocols.

Power requirements: The typical input voltage is 24V DC or 120/240V AC, and the specific model may vary.

Environmental conditions: With a wide range of working temperatures, it can adapt to harsh industrial environments and has excellent resistance to vibration and impact.

Application areas:

Process control: widely used in industries such as petroleum, chemical, and power to control complex production processes.

Mechanical automation: used for logical control, motion control, and other tasks of automated mechanical equipment.

Building Management System: Used for environmental monitoring, energy management, and other functions in intelligent building and infrastructure management systems.

Distributed Control System (DCS): As a control node, it participates in the distributed control network of large factories or production systems.

Summary:

The GE 201CI-1 controller module is a powerful and scalable industrial control device that can meet the control needs of complex industrial automation systems. It has excellent performance in logic processing, I/O connections, network communication, and is widely used in control systems in various industries.

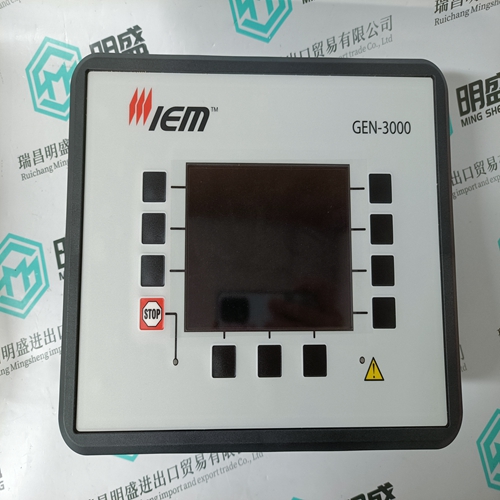

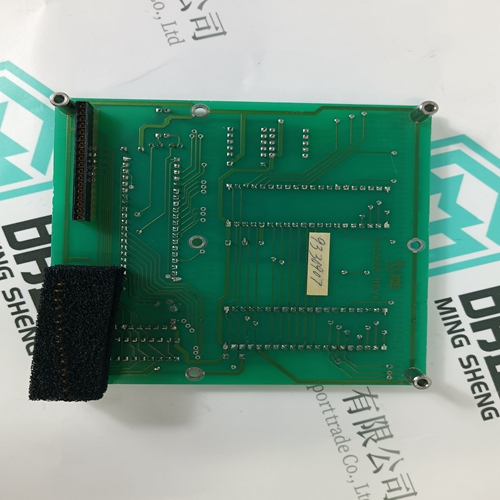

Product image

Related website links

ASEA DSCA121 Robot Control Board

Other website links

| PMB32D-00100-03 | NKLS11 | M22NRXD-LSF-SS-02 |

| PMB32D-00100-02 | 07ZE82 | P22NSHS-LNS-NS-02 |

| PMB32D-00100-01 | 70 SK 30b-E | PWM3656-5102-84-3 |

| PMB32D-00100-00 | FPR3327101R0206 | N33HLLM-LNK-NS-00 |

| PMB32C-20100-00 | AMAT 0100-77040 | 57120001-KY DSTY 101 |

| PMB32C-00100-00 | 07NG82 | P22NRXC-LNN-NS-00 |

| PMB32B-00114-00 | IIMRM02 | 57160001-K DSDO 110 |

| PMB31D-20216-03 | PMKHRMRLY12S01 | P21NSXB-LNS-NS-02 |