Home > Product > PLC programmable module > TRICONEX 3805H Data Communication Module

TRICONEX 3805H Data Communication Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

TRICONEX 3805H Data Communication Module

Product Details Introduction

The TriconeX 3805H data communication module is a high reliability industrial control equipment produced by Triconex, commonly used in process control and safety systems for critical tasks. Triconex is a redundant control system designed specifically for safety related applications, widely used in industries such as oil and gas, chemical, and nuclear power. The 3805H data communication module is an important component responsible for communication and data transmission in the Tricon system, ensuring system security and real-time data transmission.

Main functions and features:

High reliability redundancy design:

The 3805H module supports Triple Modular Redundancy (TMR) architecture, ensuring high reliability and fault tolerance of data communication in redundant systems.

Triple redundancy architecture can tolerate single module failure without affecting the overall performance of the system to ensure the continuous operation of the control system.

High speed data communication:

Supports high-speed, real-time data transmission and seamless communication with other modules and external devices in the system.

Suitable for industrial application scenarios that require big data throughput and low latency, ensuring real-time monitoring and response of the system to process data.

Wide protocol support:

3805H supports multiple industrial communication protocols, including Modbus, TCP/IP, etc., making it easy to integrate with other industrial control systems, PLCs, DCS, or SCADA systems.

The module has good compatibility and is suitable for various industrial communication environments.

Redundant network support:

This module provides redundant network communication functionality, ensuring that the system can operate normally even in the event of network failures and guaranteeing data integrity and security.

The design of redundant networks provides additional security guarantees for critical task application scenarios.

Modular design:

The 3805H module adopts a modular design, which is easy to install, expand, and maintain. It can flexibly add or replace modules according to needs, reducing downtime.

Modular design also facilitates system upgrades and ensures the sustainable development of control systems.

System integration and scalability:

The 3805H module can be seamlessly integrated with other Triconex control modules, such as input/output modules, processor modules, etc., to build highly reliable process control systems.

Strong scalability, suitable for small and large system deployment, meeting the needs of industrial applications of different scales.

Diagnostic function:

The module has built-in self diagnostic function, which can monitor the real-time operation status of the module and system, quickly detect faults and issue alarms, and reduce maintenance time.

This intelligent diagnostic function helps prevent system failures, maintain high availability and safety.

Technical specifications:

Redundant architecture: Triple Redundancy (TMR) architecture

Communication speed: Supports high-speed data communication, the specific speed depends on network configuration and communication protocol

Protocol support: Modbus, TCP/IP and other commonly used industrial protocols

Network interface: Multiple network interfaces, supporting redundant communication configuration

Diagnostic function: real-time fault detection and self diagnosis function

Operating temperature range: Suitable for harsh industrial environments, typically within the range of -20 ° C to 60 ° C

Application areas:

Oil and gas industry:

Used for upstream and downstream process control of oil and gas, ensuring production safety and long-term operation of equipment.

Chemical industry:

Used in chemical plants to monitor and control important processes such as reaction processes and pipeline transportation, ensuring safe production.

Electricity and nuclear power industry:

Redundant control and real-time data communication for safety systems in nuclear power plants and other power facilities to ensure the safety of power production and transmission.

Metallurgy and Mining:

Used for automation control and equipment protection in mines and metallurgical production lines to prevent major accidents from occurring.

Safety Instrumented System (SIS):

Widely used in safety instrumented systems in industrial processes as the communication core for emergency shutdown systems (ESD), fire and explosion prevention systems, etc.

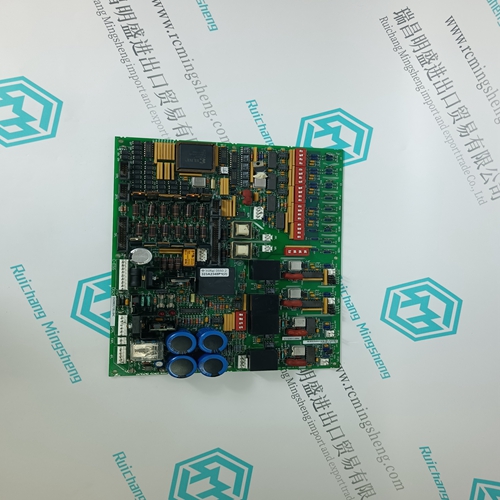

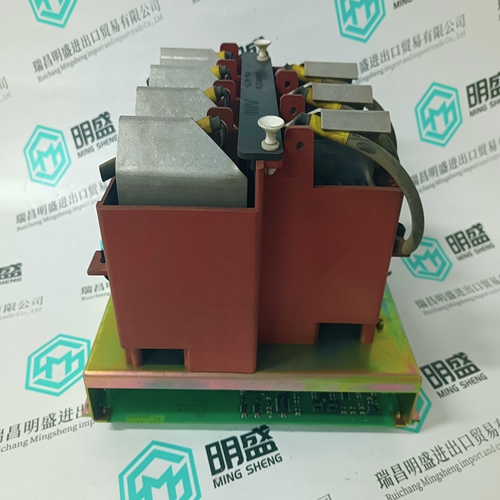

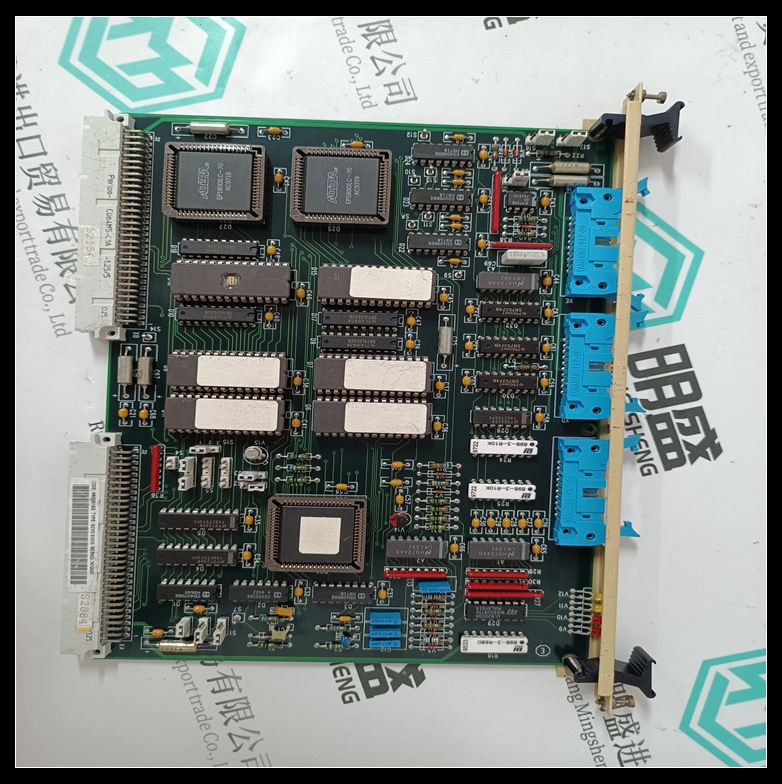

Product image

Related website links

ASEA DSCA121 Robot Control Board

ASEA DSPC150 Robot Control Board

Other website links

| PMB31D-20216-00 | AMAT 0240-31854 | PFTL101AE 1.0KN 3BSE004212R1 |

| PMB31D-20214-03 | IMSET01 | 1SAP140100R0100 |

| PMB31D-20214-02 | NKTU010 | M22NSLS-LDN-M1-02 |

| PMB31D-20214-01 | IMMFC05 | 3BSE003832R1 SC510 |

| PMB31D-20214-00 | INICT03A | KEBA |

| PMB31D-20201-03 | 07ZB69R1 | P21NRFB-LNN-NS-00 |

| PMB31D-20201-02 | NKTU01 | M22NSXD-LNN-NS-02 |

| PMB31D-20201-01 | NKMP01 | M21NRFC-LSS-HD-02 |