Home > Product > Servo control system > Bently 3500/54 133396-01 Displacement Monitor

Bently 3500/54 133396-01 Displacement Monitor

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Bently 3500/54 133396-01 Displacement Monitor

Product Details Introduction

The Bently 3500/54 133396-01 displacement monitor is a critical monitoring module produced by GE Bently Nevada, designed specifically for machine condition monitoring and protection. It belongs to the 3500 series monitoring system and is widely used for displacement monitoring of large rotating machinery equipment, including industrial equipment such as turbines, compressors, generators, and pumps.

Main functions and features:

Real time displacement monitoring:

This displacement monitor is specifically designed to monitor the axial or radial displacement of rotating machinery. It detects the displacement of the equipment axis through high-precision sensors to prevent mechanical damage or failure caused by displacement exceeding the specified range.

Real time monitoring can help predict potential equipment failures and perform preventive maintenance.

High precision measurement:

The 3500/54 adopts advanced measurement technology and is capable of high-precision monitoring of displacement. Accurate displacement data can be used to evaluate the operating status of machines and automatically trigger alarms or shutdowns through the system to avoid accidents.

Especially suitable for applications that require high-precision displacement measurement, such as high-speed rotating machinery.

Multi channel design:

This monitor supports multiple input channels and can simultaneously monitor the displacement of multiple axes. This multi-channel design improves monitoring efficiency and is suitable for use in complex mechanical equipment.

Each channel can be independently configured to meet the monitoring needs of different devices.

Integration with 3500 series systems:

The Bently 3500/54 module is part of the 3500 series online monitoring and protection system, which can be seamlessly integrated into existing 3500 systems and work in conjunction with other modules to provide comprehensive equipment status monitoring and protection.

This module can be used in conjunction with vibration monitoring module, speed monitoring module, etc. to provide comprehensive monitoring for the equipment.

Alarm and protection functions:

This module can set alarm limits. When the displacement exceeds the set value, the system will automatically trigger an alarm or initiate protective actions, such as slowing down or shutting down the equipment.

The monitor has a two-level alarm (warning and danger) setting, which can provide timely feedback at different displacement levels.

Advanced data processing and display:

The monitor supports digital processing and can analyze and process the collected data, and display the device displacement status in real-time through a display terminal or remote system.

Data can be stored and used for subsequent fault analysis and diagnosis, helping to optimize equipment operation and maintenance plans.

Reliability and Durability:

The Bently 3500 series is designed for harsh industrial environments and can maintain reliable operation under high temperatures, vibrations, and other harsh conditions. The module structure is sturdy and suitable for long-term online monitoring.

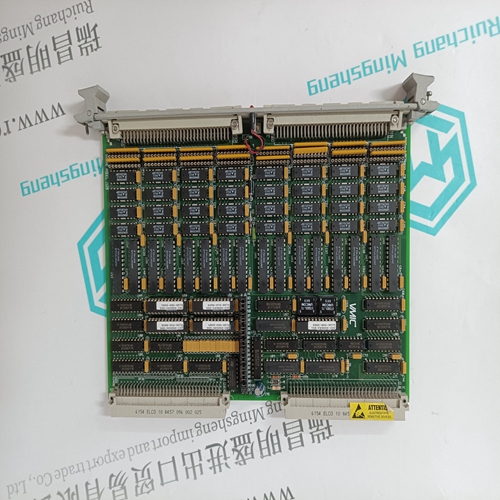

Product image

Related website links

ASEA SNAT7600 driver control circuit board

Other website links

| PMB31D-20114-01 | 07PS62R1 | P22NRXA-LDF-M1-00 |

| PMB31D-20114-00 | 70 BL 31a | N43HRLN-LDK-NS-00 |

| PMB31D-20101-03 | 07KP90 | P22NRXB-LNF-NS-00 |

| PMB31D-20101-02 | AMAT 0100-00244 | PFTL301E 3BSE019050R0500 |

| PMB31D-20101-01 | NIAI01 | PMB33F-20200-01 |

| PMB31D-20101-00 | 07ZE61R101 | P21NSHS-LNF-NS-02 |

| PMB31D-20100-03 | IMDrSM05 | 3BSX426978R2 DSTK 150 |

| PMB31D-20100-02 | AMAT 0100-71229 | PFTL101A 0.5KN 3BSE004160R1 |