Home > Product > DCS control system > Brooks 002-1600-25 wafer transfer robot

Brooks 002-1600-25 wafer transfer robot

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

Brooks 002-1600-25 wafer transfer robot

Product Details Introduction

Brooks 002-1600-25 is a robot specifically designed for wafer transfer in semiconductor manufacturing processes. It is a high-precision, automated equipment produced by Brooks Automation, widely used in semiconductor, microelectronics, and other high-precision manufacturing fields, especially playing a crucial role in wafer processing, handling, loading and unloading, and transportation processes.

Main features and specifications

Application areas:

Mainly used for automated transfer in semiconductor wafer production lines, ensuring seamless docking of wafers from one process to another.

Used for high-precision wafer loading, unloading, and handling tasks in clean environments such as cleanrooms.

Design and Construction:

This model of robot has highly automated functions and can accurately move wafers from one position to another.

The design takes into account extremely low vibration and pollution, making it suitable for the demanding requirements of cleanliness and accuracy in semiconductor manufacturing processes.

Equipped with high-precision control systems, typically including visual recognition and sensors, to ensure that each transferred wafer is in the correct position.

Performance characteristics:

High speed automation: capable of quickly and effectively executing tasks, reducing production line downtime.

High precision: During wafer handling, the robot's precision can reach micrometer level, ensuring that the wafer is not damaged and always in a stable position.

Strong environmental adaptability: suitable for clean room environments and meets the cleanliness standards of the semiconductor industry.

High reliability: usually equipped with redundant systems to ensure stable operation even under extreme working conditions.

Control system and interface:

Usually equipped with high-end control systems, it supports integration with factory automation systems and can achieve coordinated work with other production equipment.

Provide interfaces to connect with factory information systems (such as MES, SCADA) for real-time monitoring of equipment status, task scheduling, fault diagnosis, etc.

working principle:

Robots transfer wafers from one area to another through robotic arms or similar motion devices. The motion control system ensures precise execution of actions and avoids damaging the wafer.

Equipped with high-precision sensors and vision systems, it can detect the position, status, and surrounding environment of the wafer, achieving intelligent dynamic adjustment.

Size and load capacity:

This robot typically has a high load capacity and can handle multiple wafers simultaneously, or handle wafers of different sizes (such as 200mm and 300mm wafers).

The size and load capacity of the equipment depend on the specific model and configuration.

Applicable scenarios

Wafer manufacturing: In wafer processing plants, robots can achieve full process automation from raw material processing to processing, testing, and packaging.

Clean room handling: Using such robots in a clean room environment can minimize human interference and pollution sources, improve production efficiency and product quality.

Efficient production: Through high automation and intelligence, reducing manual intervention and operational errors, improving production stability and efficiency.

summary

The Brooks 002-1600-25 wafer transfer robot is a high-precision automation equipment designed specifically for the semiconductor industry, with efficient and reliable wafer handling capabilities. It can help semiconductor production lines achieve automation and intelligence, reduce operational risks, improve production efficiency, and ensure the safe transportation of each wafer.

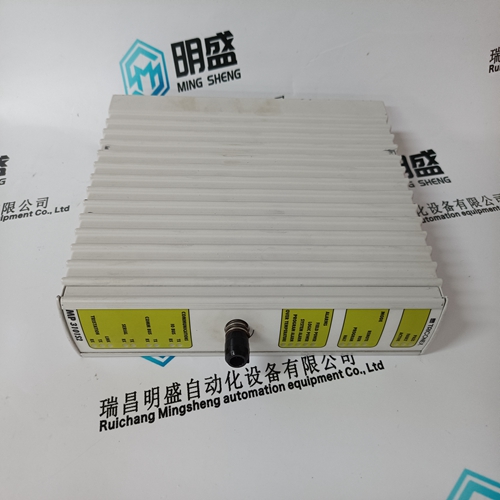

Product image

Related website links

RADISYS 97-9536-20 Ethernet Port Module

RADISYS 451558-004 Communication Module

Other website links

ABB REG670 1MRK002826-AC 安全系统组件

| PMB31D-10101-01 | 07YS81 | P21NSXC-LNN-NS-04 |

| PMB31D-10101-00 | Amat 0100-02839 | 57170001-A DSXS 001 |

| PMB31D-10100-03 | PHAREPRFO10000 | M22NRFB-LDN-NS-00 |

| PMB31D-10100-02 | IPFLD01 | 61031 Terminal Block, Relay |

| PMB31D-10100-01 | AMAT 0100-00853 | PFVL141R |

| PMB31D-10100-00 | AMAT 0100-09362 | PFEA111 |

| PMB31D-00216-03 | IMDSO14 | 3ASD573001A13 YPK112A |

| PMB31D-00216-02 | AMAT 0100-01456 | 57120001-KH DSTA 156 |