Home > Product > PLC programmable module > BROOKS 162770-01 Semiconductor Wafer Load Port

BROOKS 162770-01 Semiconductor Wafer Load Port

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

BROOKS 162770-01 Semiconductor Wafer Load Port

Product Details Introduction

Brooks 162770-01 Semiconductor Wafer Load Port is a device used in semiconductor manufacturing processes, specifically designed to carry and transport wafer pods (typically 200mm or 300mm) and connect them to automation systems to ensure the flow and handling of wafers between different processes. This load port is an important component of material handling in semiconductor production lines, capable of transferring wafers from one equipment or processing station to another, playing a role in carrying, docking, and transferring wafers.

Main features and specifications

Application areas:

In the semiconductor manufacturing process, load ports are mainly used to load wafers from an automation module (such as a wafer transfer robot or handling system) to the next device.

It is commonly used in multiple semiconductor processing steps such as wafer cleaning, exposure, etching, chemical mechanical polishing, etc.

Suitable for cleanroom environments, it can ensure the cleanliness requirements of the semiconductor manufacturing process and avoid pollution.

Design and Construction:

Modular design: Load ports typically have a modular design that can be flexibly configured according to production line requirements, supporting loads of different sizes of wafer boxes (such as 200mm or 300mm).

High precision docking: This port design ensures precise docking of the wafer box, avoiding any physical damage or positional deviation, and reducing errors during the machining process.

Stable mechanical structure: Its mechanical structure has been precisely designed to withstand different weights and sizes of crystal round boxes, while providing high stability.

Performance characteristics:

High reliability: The Brooks 162770-01 load port has strong durability and can withstand long-term operation, ensuring stable wafer transfer.

Dust free design: Designed to meet cleanroom standards, it can effectively avoid the generation of pollutants in the semiconductor production process.

Automation: Typically integrated with automated transmission systems, robots, or other equipment, capable of operating in fully automatic mode with minimal human intervention.

working principle:

Automatic docking: The load port is usually docked with an automated handling system. When the wafer box arrives, the equipment will automatically align and transfer it to the next processing stage.

Accurate transmission: Through a precise control system, the load port can accurately control the position and direction of the wafer box, ensuring that the wafer is always in the appropriate position.

Transmission method: The load port usually sends the wafer box into the corresponding equipment through mechanical arms, slides, or pneumatic systems.

Control system and interface:

This load port is usually equipped with an automation control system that can interact with MES (Manufacturing Execution System), SCADA system, and other equipment on the production line, providing real-time equipment status monitoring and fault alarms.

Support seamless connection with other semiconductor automation equipment to ensure automation and efficient collaboration throughout the entire production process.

Size and load capacity:

This model of load port typically supports loads of 200mm and 300mm standard wafer boxes, which can meet the needs of most semiconductor manufacturing processes.

The load capacity varies depending on the specific configuration, but it is usually designed to support multiple wafer boxes, ensuring continuous and stable production.

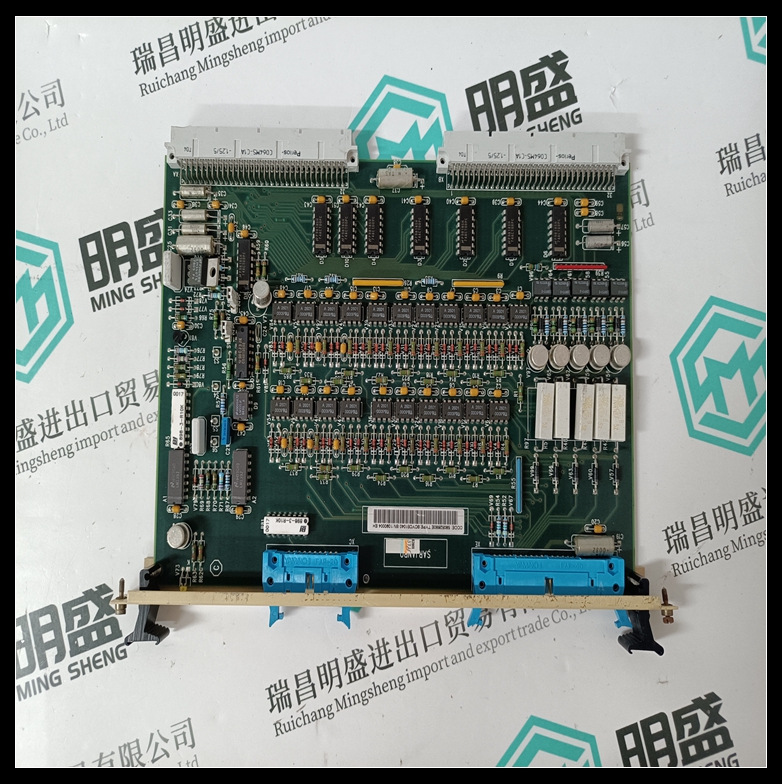

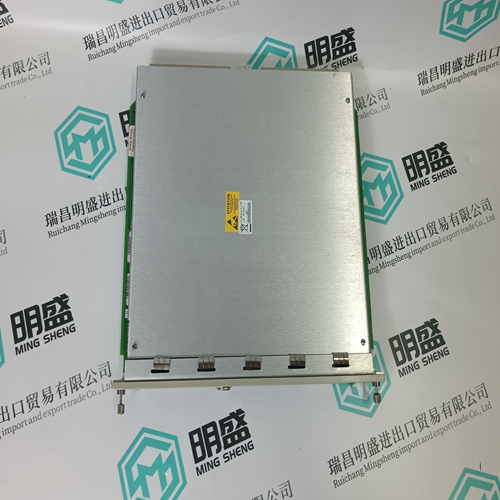

Product image

Related website links

ABB XVC768117 Field Input/Output Module

Other website links

KOLLMORGEN S70602-PBNANA 伺服驱动控制器

ABB UFC760BE01 3BHB007030R0001 可编程控制器

| PMB31D-10100-00 | AMAT 0100-09362 | PFEA111 |

| PMB31D-00216-03 | IMDSO14 | 3ASD573001A13 YPK112A |

| PMB31D-00216-02 | AMAT 0100-01456 | 57120001-KH DSTA 156 |

| PMB31D-00216-01 | 70 VV 01a | R32GENC-TS-NS-VS-00 |

| PMB31D-00216-00 | AMAT 0100-71267 | 57160001-P DSTD 120 |

| PMB31D-00214-03 | 70 WA 01a-E | R32HSNG-TS-NS-NV-02 |

| PMB31D-00214-02 | AMAT 130-0401 | 57160001-TK DSDI 141A |