Home > Product > PLC programmable module > Brooks 002-7391-11 wafer aligner

Brooks 002-7391-11 wafer aligner

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Brooks 002-7391-11 wafer aligner

Product Details Introduction

The Brooks 002-7391-11 wafer aligner is a critical equipment provided by Brooks Automation, designed specifically for precise alignment of wafers in semiconductor manufacturing processes. Wafer aligners play a crucial role in semiconductor processing, etching, photolithography, and other precision manufacturing processes, ensuring accurate positioning of wafers at various stages of processing.

Main features and functions:

High precision alignment:

The Brooks 002-7391-11 wafer aligner provides extremely high positioning accuracy and can accurately align various shapes or marks on the wafer circle. This is crucial for precision processes such as photolithography, etching, and thin film deposition, ensuring that each processing meets the required high precision requirements.

Automated operation:

Wafer aligners are typically equipped with automated operating systems that can automatically adjust the position and angle of wafers, reducing manual intervention and improving production efficiency and accuracy. Automation functions can also reduce errors and improve overall production process consistency.

Strong adaptability:

This device can accommodate multiple wafer sizes and types, typically suitable for alignment of 200mm (8 inches) and 300mm (12 inches) wafers, and can also support wafers of other sizes as needed. The design of wafer aligners is flexible and compatible with various wafer carriers and processing equipment.

Real time detection and feedback:

The wafer alignment device is equipped with high-precision sensors and camera systems, which can monitor the alignment status of the wafer in real time, detect any deviations, and provide feedback. The system can automatically perform fine adjustments to ensure precise wafer alignment and avoid deviations during the production process.

Support multi station operation:

In some applications, wafer aligners support multi station operations and can accurately align multiple wafers simultaneously, improving production efficiency. Multi station support can significantly improve the automation level of large-scale production lines.

High stability and durability:

The design of Brooks 002-7391-11 wafer aligner emphasizes stability and durability, especially in clean room environments and long-term operating conditions, it can maintain high efficiency, reduce failures and maintenance costs. High quality mechanical components and materials ensure their stability in high-strength applications.

Accurate motion control:

Aligners are typically equipped with precision motion control systems that ensure precise movement and alignment of wafers during operation. A precise motion control system can minimize the deviation of wafer position to the greatest extent possible.

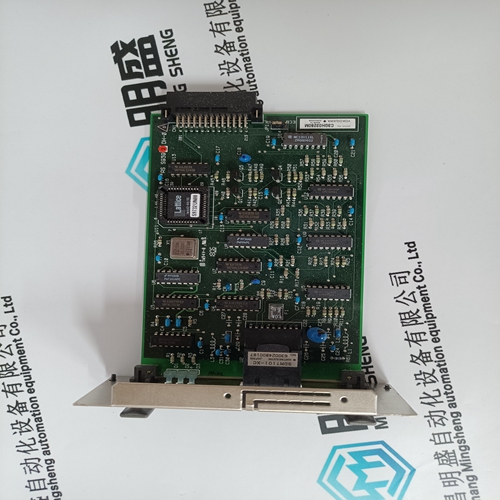

Product image

Related website links

RADISYS 061-05927-0031 adapter module

Radisys EPC-3307 processor board

Radisys ATCA-PP81 controller module

Other website links

| PMB31D-00200-03 | NIAI02 | PMB33F-20116-02 |

| PMB31D-00200-02 | INSEM01 | XV 77135 |

| PMB31D-00200-01 | AMAT 0100-00061 | PFVL141V |

| PMB31D-00200-00 | 07NG63R1 | P22NRXC-LSN-NS-02 |

| PMB31D-00116-03 | IMDSO01 | 3BUR001953R1 DSTX 180 |

| PMB31D-00116-02 | 70 AB 01b-E | N42HRFN-LNK-NS-00 |

| PMB31D-00116-01 | 07NG68R1 | P21NSXS-LNN-NS-02 |

| PMB31D-00116-00 | AMAT 0100-09028 | PFTL101B 5.0KN 3BSE004191R1 |