Home > Product > DCS control system > Brooks 486DX2 wafer robot controller

Brooks 486DX2 wafer robot controller

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Brooks 486DX2 wafer robot controller

Product Details Introduction

The Brooks 486DX2 wafer robot controller is a controller designed specifically for wafer handling and automation systems in semiconductor manufacturing environments. It is typically integrated into automated equipment for wafer transfer and processing, helping to achieve efficient and precise wafer handling processes. Here are some key features and applications of the controller:

Main features:

High performance processor:

486DX2 is a high-performance processor based on Intel 486 architecture, which has high computing power and data processing speed, and can quickly respond to the needs of robot control systems.

Even though the processor is relatively outdated, it was widely used in early semiconductor automation equipment, with stable computing performance that can meet most basic control requirements.

Multi axis motion control:

This controller supports multi axis robot control and is typically used to control four - or six axis robotic arms or other types of automation devices. The controller can accurately coordinate the movements of different axes to ensure positional accuracy and smooth motion during wafer handling.

Real time control capability:

The Brooks 486DX2 controller has real-time processing capabilities and can quickly respond to input signals, enabling precise robot operations. This feature is crucial for wafer handling tasks as it ensures the accuracy of each handling and avoids damage or contamination of the wafer.

I/O interface:

Equipped with multiple input/output interfaces for connecting sensors, actuators, and other automation devices, ensuring that the robot can effectively communicate and interact with external systems.

Common interfaces include digital input/output, analog input/output, and serial communication interfaces (such as RS-232, RS-485).

Programming and Debugging:

This controller typically supports custom programming and can be configured and debugged using different programming languages. Common programming methods include G-code or specific robot programming languages.

For debugging and maintenance, the system provides detailed diagnostic functions that can help engineers troubleshoot and optimize performance.

Reliability and stability:

Reliability and stability are crucial in the wafer handling environment. The Brooks 486DX2 controller is designed to operate in harsh production environments for extended periods of time and can withstand certain temperatures, humidity, and electromagnetic interference.

Compatibility with other systems:

The Brooks 486DX2 controller is typically compatible with devices and systems from other manufacturers, and can be connected to upper computers or other automation control systems through standardized communication protocols such as SECS/GEM, Modbus, etc.

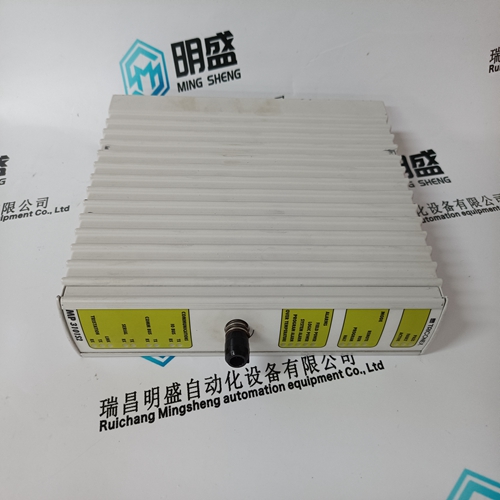

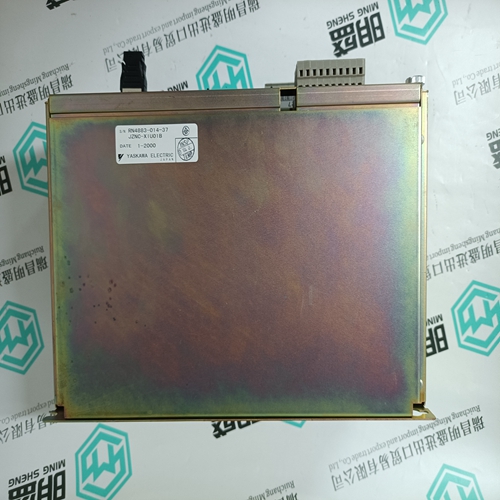

Product image

Related website links

ABB UN0807C-P Programmable Controller

HE700GEN200 Network Interface Module

Other website links

| PMB31B-00201-00 | AMAT 0100-71261 | 57120001-KD DSTA 155 |

| PMB31B-00200-03 | NKTU117 | M22NRXD-LNN-NS-00 |

| PMB31B-00200-02 | AMAT 0110-00001 | 57160001-KX DSDO 131 |

| PMB31B-00200-01 | IMASO01 | 3BSE004255R1 SX542 |

| PMB31B-00200-00 | 70 AS 32a-E | N33HCLG-LNK-NS-01 |

| PMB31B-00116-03 | AMAT 0100-71282 | PFCL201 10.0KN |

| PMB31B-00116-02 | IMHSS02 | 3BSE000863R1 SR511 |

| PMB31B-00116-01 | AMAT 0100-20078 | PFTL101AE 0.5KN 3BSE004211R1 |