Home > Product > Robot control system > Brooks 002-7090-11 wafer transfer robot

Brooks 002-7090-11 wafer transfer robot

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Brooks 002-7090-11 wafer transfer robot

Product Details Introduction

The Brooks 002-7090-11 wafer transfer robot is a high-performance wafer handling robot designed by Brooks Automation specifically for the semiconductor and electronic manufacturing industries. This robot is used to transport wafers between different process equipment, helping to achieve automation, precision, and efficiency in the production process. It is widely used in multiple stages of semiconductor manufacturing, such as wafer cleaning, etching, coating, exposure, and inspection processes.

Main features:

High precision positioning and handling:

The Brooks 002-7090-11 robot adopts advanced positioning technology, which can achieve sub micron level positioning accuracy and ensure accurate positioning of wafers during transportation.

The handling system has been optimized to maintain stability at high speeds, reduce vibration during wafer transport, and minimize potential damage to the wafer surface.

Multi degree of freedom motion control:

Equipped with a multi axis and multi degree of freedom control system, the wafer can be moved and rotated on different planes to meet the precise requirements of complex processes for position and angle. This feature is particularly suitable for process steps that require adjusting wafer orientation or height.

Cleanroom compatibility:

Designed to meet the cleanroom standards of the semiconductor industry, with low particle emission characteristics, capable of long-term stable operation in ultra clean environments, and avoiding contamination of wafer surfaces.

The material and design have been optimized to operate in high demand environments in clean rooms while reducing maintenance requirements.

High speed transmission capability:

The Brooks 002-7090-11 robot has fast handling capabilities while maintaining accuracy, which helps shorten the transfer time between process equipment and improve production efficiency.

Supports continuous handling of multiple wafers, suitable for high-yield production lines, optimizing the overall speed of the manufacturing process.

Modular design and flexibility:

Adopting modular design, it can be easily integrated into different automation equipment or production lines, with strong adaptability. Users can flexibly configure according to production needs, making it easy to expand and upgrade.

Support integration with other Brooks devices and third-party control systems to ensure compatibility and consistency of the entire automation system.

Intelligent control and feedback system:

Equipped with an intelligent control system that supports real-time monitoring and position adjustment, it can automatically correct the wafer position to ensure stability and accuracy during the handling process.

Equipped with self diagnostic function, it can detect and provide feedback on its own operating status, reduce downtime, and facilitate timely response by operation and maintenance personnel.

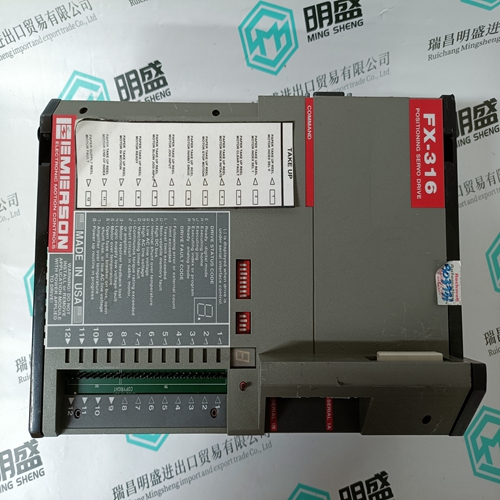

Product image

Related website links

AFP9075355 3BHS537443 voltage regulator

DS200TCEAG1BNE emergency overspeed board

YT204001-KA/5 voltage signal regulator

Other website links

KOLLMORGEN 60WKS-CE240 22PB 伺服驱动器

| PMB11D-10Y16-10 | GJR5252100R0201 | N41HRFM-LNK-NS-00 |

| PMB11B-10Y14-04 | IMFEC11 | 3BSE000435R1 SC513 |

| PMB11B-00114-00 | GJR5251300R0161 | N31HCLK-LNK-NS-00 |

| PMA67S-11100-00 | AMAT 0100-A2523 | PFTL101AE-1.0KN 3BSE004212R1 1.0KN |

| PMA67S-10100-00 | AMAT 0100-01132 | PFTL101B-10KN 3BSE004197R1 |

| PMA65S-10100-00 | AMAT 0100-01222 | PFTL101AER-0.5KN 3BSE023010R1 |

| PMA65R-11100-00 | AMAT 0100-76267 | PFTL101B 50KN |

| PMA57S-11100-00 | AMAT 0100-09020 | PFTL-101B 5KN 3BSE00418SR1 |

| PMA57R-10100-00 | AMAT 0100-90221 | PFTL101B-2.0KN 3BSE004185R1 2.0KN |