Home > Product > Gas turbine system > Brooks 02-169208-00 Wafer Processing Robot

Brooks 02-169208-00 Wafer Processing Robot

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Brooks 02-169208-00 Wafer Processing Robot

Product Details Introduction

The Brooks 02-169208-00 wafer processing robot is an automated robot designed by Brooks Automation specifically for semiconductor manufacturing and wafer processing. This robot is used for precise handling, positioning, and transportation in wafer processing processes, and is suitable for high cleanliness environments such as cleanrooms. Its reliable design, precise control system, and efficient handling capability make it an important tool in semiconductor production and testing processes.

Main features:

High precision handling:

The Brooks 02-169208-00 robot is capable of achieving micrometer level wafer positioning, ensuring the accuracy of the wafer during transportation. Its high-precision design meets the demand for minimal error tolerance in semiconductor manufacturing.

Its control system provides a smooth and stable motion path, thereby reducing the vibration of the wafer during transportation and lowering the risk of wafer damage.

Multi axis control and flexible operation:

Equipped with a multi axis control system, supporting free movement in multiple directions and angles. Robots can easily perform complex movements such as translation, rotation, and tilt to meet the different import and export needs of various devices.

The flexible design enables it to operate freely in small or complex equipment arrangements, increasing the diversity of production line layouts.

High speed handling capacity:

This robot is able to complete wafer handling at a faster speed, optimizing the transfer time between process steps and thus improving the efficiency of the entire production line. Its rapid response system ensures high-speed transmission while maintaining accuracy.

Cleanroom compatible design:

The material and structural design of Brooks 02-169208-00 meet the strict standards of cleanrooms, with low particle generation and low contamination risk, suitable for long-term stable operation in cleanroom environments, and protecting wafers from contamination.

The dust-proof design and high durability materials enable it to operate in clean rooms and minimize interference with the environment.

Intelligent monitoring and self diagnosis:

Equipped with an intelligent monitoring system, it can monitor the handling and operation status in real time, and provide fault detection and diagnosis functions. This self diagnostic function can help the operations team discover and solve problems in a timely manner, reducing the risk of unexpected downtime.

Support connection with the upper computer, capable of analyzing and recording data on operating status, performance indicators, etc., to help optimize production efficiency.

Modular design:

Designed with a modular structure, it is easy to integrate with other Brooks equipment or third-party wafer processing equipment. Modular design facilitates expansion, upgrading, and maintenance, providing support for the flexibility of production lines.

This feature enables it to be configured and adjusted according to specific needs to meet the requirements of different wafer sizes or process flows.

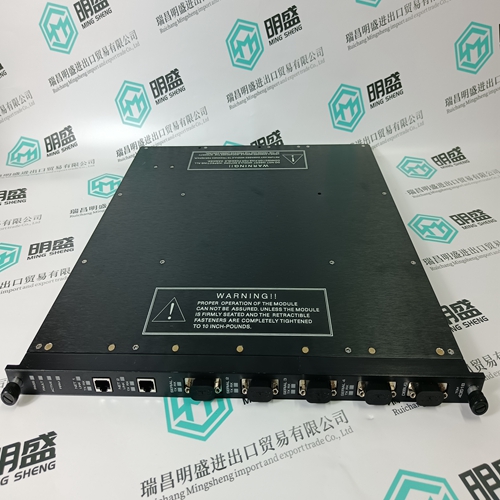

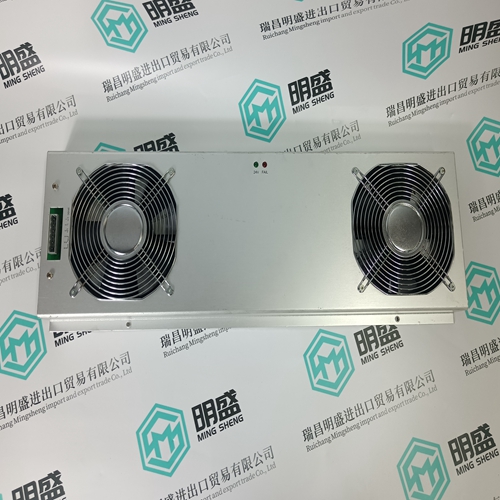

Product image

Related website links

YT204001-KA/5 voltage signal regulator

VMIVME-2540 Intelligent Counter Controll

Mitsubishi MELFA CR1-571 Large Contactor

Other website links

KOLLMORGEN 60WKS-CE240 22PB 伺服驱动器

GE 516TX 336A4940DNP516TX 输入输出模块

| PMA57R-00100-00 | AMAT 0100-00042 | PFTL201D |

| PMA55S-10100-00 | AMAT 0100-00005 | PFTL101BER |

| PMA55R-10100-00 | AMAT 0100-02706 | PFTL101AER-2.0KN 3BSE023012R1 2.0KN |

| PMA55R-00100-00 | AMAT 0100-09153 | PFTL201C |

| PMA55Q-10100-00 | AMAT 0100-00048 | PFTL101BER-2.0KN 3BSE023158R1 2.0KN |

| PMA54R-10100-00 | AMAT 0100-01135 | PFTL101B |

| PMA54R-00100-00 | AMAT 0100-09041 | PFTL101B-2.0KN 3BSE004191R1 |

| PMA54Q-11100-00 | Amat 0100-03499 | PFTL101BE |