Home > Product > Gas turbine system > Brooks 2002-0066 Controller Module

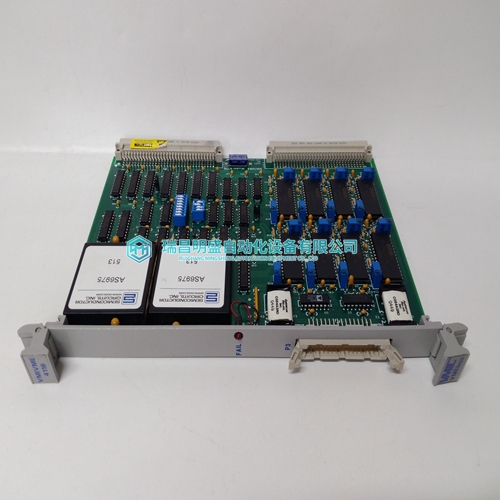

Brooks 2002-0066 Controller Module

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Brooks 2002-0066 Controller Module

Product Details Introduction

The Brooks 2002-0066 controller module is a high-performance control module designed for industrial automation and precision control systems. This module is mainly used in various complex industrial application environments, providing precise control and real-time monitoring for equipment. The Brooks 2002-0066 controller module performs well in high load, high-precision tasks and is suitable for scenarios that require highly stable control, such as semiconductor manufacturing, automated production lines, and laboratory equipment.

main features

High precision control: supports multi axis synchronous control and precise positioning, suitable for applications that require complex motion management.

Real time data processing: Equipped with efficient processors to ensure real-time data collection and response, supporting multitasking parallel processing.

Flexible integration: The modular structure facilitates integration into different automation systems and can adapt to various production needs.

Multi communication interface: Supports multiple industrial communication protocols (such as RS-232, CAN, Ethernet, etc.) for easy interconnection with other control modules, sensors, and peripheral devices.

Durable and sturdy: Designed for harsh industrial environments, it has high temperature resistance and shock resistance, and can operate stably for a long time.

Programmable: Supports customized programming and control logic configuration, adapting to diverse control needs.

application area

Semiconductor manufacturing: can be used for precise control of equipment such as wafer processing and transmission systems, improving production quality and efficiency.

Industrial automation production: suitable for equipment control on automated assembly lines, such as robot arms, conveyor systems, etc.

Laboratory automation: used in experimental equipment to control and collect high-precision data, ensuring operational consistency and data accuracy.

Precision machining: used for CNC machine tools, laser processing and other equipment that require high control precision to improve machining accuracy.

Overview of Technical Specifications

Power requirement: Generally 24V DC (specific voltage requirement depends on the actual model).

Processing capability: Supports real-time control tasks, can effectively handle complex instructions and respond quickly.

Communication interface: Supports RS-232, CAN, Ethernet, etc., ensuring smooth data exchange between devices.

Working temperature: The typical working temperature range is 0 ° C to 50 ° C, meeting the needs of industrial applications.

Size: Modular design, compact structure, easy to install in various control cabinets or equipment.

Product image

Related website links

REF615E-E HBFEAEAGABCCANC11E Measurement

KOLLMORGEN S70602-NANANA servo/driver

Other website links

| PMA57R-00100-00 | AMAT 0100-00042 | PFTL201D |

| PMA55S-10100-00 | AMAT 0100-00005 | PFTL101BER |

| PMA55R-10100-00 | AMAT 0100-02706 | PFTL101AER-2.0KN 3BSE023012R1 2.0KN |

| PMA55R-00100-00 | AMAT 0100-09153 | PFTL201C |

| PMA55Q-10100-00 | AMAT 0100-00048 | PFTL101BER-2.0KN 3BSE023158R1 2.0KN |

| PMA54R-10100-00 | AMAT 0100-01135 | PFTL101B |

| PMA54R-00100-00 | AMAT 0100-09041 | PFTL101B-2.0KN 3BSE004191R1 |

| PMA54Q-11100-00 | Amat 0100-03499 | PFTL101BE |