Home > Product > Gas turbine system > Brooks 001-7124-01 Robot Controller Board

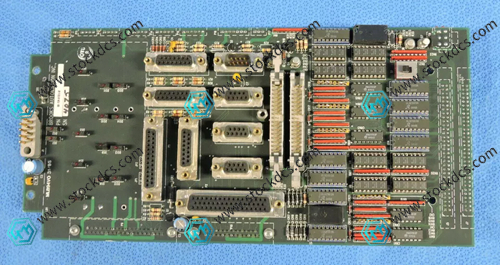

Brooks 001-7124-01 Robot Controller Board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:

- Get the latest price:Click to consult

Brooks 001-7124-01 Robot Controller Board

Product Details Introduction

The Brooks 001-7124-01 robot controller board is a high-performance controller board provided by Brooks Automation, designed specifically for industrial robot systems, responsible for robot motion control, task scheduling, data processing, and system coordination. As a core component in robot control systems, it ensures that robots can perform tasks accurately while efficiently coordinating with other systems and devices.

Product features:

Precise motion control: The Brooks 001-7124-01 robot controller board can accurately control the motion of each joint of the robot, supporting high-speed and high-precision motion trajectory planning and real-time feedback, ensuring the stability and accuracy of the robot in complex operations.

Multi channel input/output: Supports multiple input/output interfaces, including digital and analog signal input, PWM output, pulse output, etc., enabling efficient signal exchange with sensors, actuators, and other devices.

Real time control capability: Equipped with a built-in high-speed processor and dedicated motion control unit, it can respond to external signal changes at the microsecond level, adapting to high-speed and real-time control requirements.

Advanced programming and debugging functions: Supports advanced programming functions and debugging tools, can customize control according to different application requirements, and provides convenient programming interfaces for developers to integrate the system.

High reliability: The controller board adopts industrial grade design, with strong anti-interference ability and high temperature resistance, suitable for various harsh working environments, ensuring the long-term stable operation of the robot system.

Communication and integration capabilities: Compatible with multiple industrial communication protocols (such as RS-485, Ethernet, CAN, etc.), supporting seamless integration with other devices and control systems.

Technical parameters:

Model: Brooks 001-7124-01

Input/output interface:

Multi channel digital and analog signal input and output.

Supports pulse control output, suitable for motor drive control.

Support the connection of external sensors and actuators.

Processing capability: Integrated high-speed processor, supports multitasking parallel processing, and can respond to control signals in real time.

Programming Interface: Supports custom motion control algorithms and task scheduling, with programmable interfaces for easy integration with other automation systems.

Working temperature range: typically -10 ° C to+60 ° C, suitable for various industrial environments.

Power requirement: 24V DC power supply or other common industrial power supply.

Communication protocol: Supports various industrial standard protocols such as RS-485, CAN bus, Ethernet, etc.

Protection mechanism: It has functions such as overheating and overload protection to ensure the safe operation of the system.

Application areas:

Industrial robots: widely used in various types of industrial robot systems, such as welding robots, assembly robots, handling robots, etc., responsible for precise control of the robot's motion trajectory, operation tasks, and coordination of various robotic arms and actuators.

Automated production line: used in the control system of automated production lines, collaborative robots work in coordination with other automation equipment (such as conveyor belts, robotic arms, etc.) to improve production efficiency.

Laboratory Automation: In laboratory automation systems, the Brooks 001-7124-01 robot controller board can be used for controlling robot operations, such as automatic sample processing, testing equipment control, etc.

Precision assembly and machining: used in precision assembly and machining tasks to ensure that robots can perform tasks with high precision, such as micro component assembly, precision machining, etc.

Logistics automation: used for robot control in logistics systems, such as automated warehousing, handling, packaging, and other tasks.

Summary:

The Brooks 001-7124-01 robot controller board is a high-performance and stable robot control core module that provides precise motion control, real-time feedback, and highly flexible programming interfaces. It is widely used in industrial automation, laboratory automation, precision assembly, logistics automation and other fields to ensure the precise execution of robots in complex tasks. With its high reliability and powerful integration capabilities, Brooks 001-7124-01 can significantly improve the performance and efficiency of robot systems.

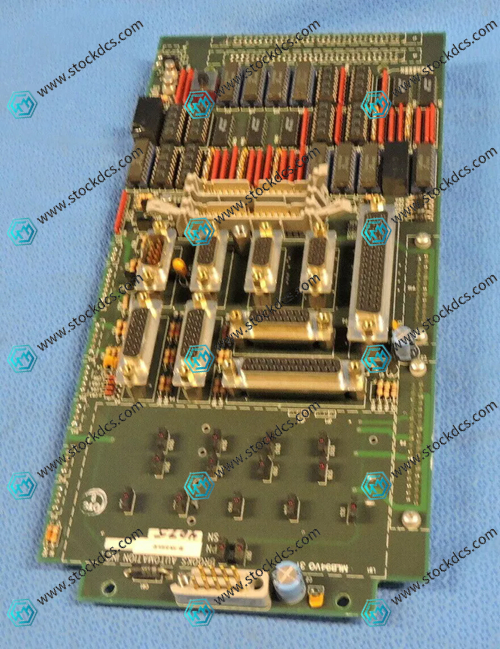

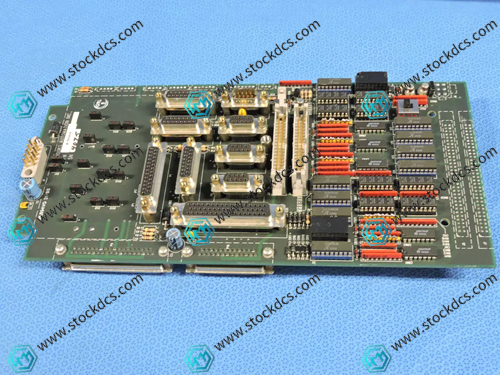

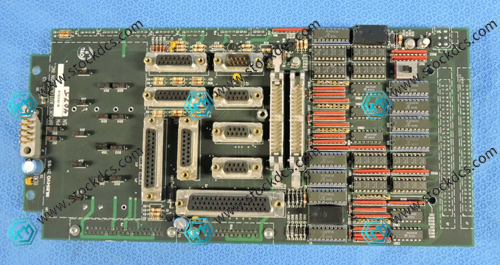

Product image

Related website links

HE700GEN200 Network Interface Module

DEIF LSU-113DG voltage regulator

AFP9075355 3BHS537443 voltage regulator

Other website links

KOLLMORGEN AKM42E-EKGNR-01伺服电机

| PMA53R-00100-00 | AMAT 0100-09081 | PFTL201CE |

| PMA53Q-10100-00 | AMAT 0100-20091 | PFTL201DE |

| PMA53Q-00100-00 | AMAT 0100-20321 | PFTL101BE-2.0KN 3BSE004214R1 2.0KN |

| PMA45R-11100-02 | AMAT 0100-20054 | PFTL101AER-1.0KN 3BSE023011R1 1.0KN |

| PMA45R-01100-00 | AMAT 0100-20060 | PFEA112-IP65 3BSE050091R65 |

| PMA45R-00100-00 | AMAT 0100-00127 | PFTL 101A-0.5 |

| PMA45Q-10100-00 | AMAT 0100-00177 | PFRL101A 0.5KN |

| PMA45N-01100-00 | AMAT 0100-35263 | PFRL101D |