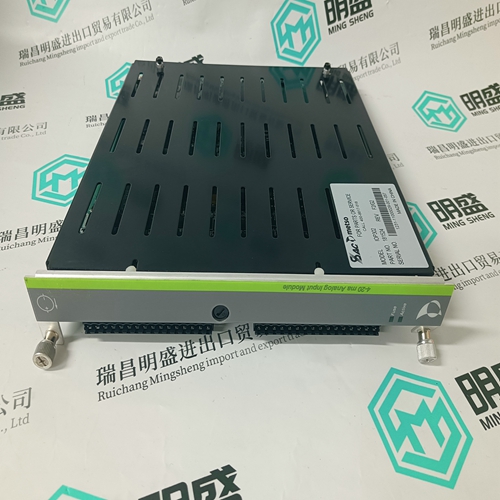

Home > Product > DCS control system > 12P2532X162-233A Input/output module

12P2532X162-233A Input/output module

- Product ID: 12P2532X162-233A

- Brand: EMERSON

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:12P2532X162-233AInput/output module

- Get the latest price:Click to consult

12P2532X162-233A Input/output module

It is the responsibility of the user to keep enough LI segments in the DMC-21x2/21x3 sequence buffer to ensure continuous motion. If the controller receives no additional LI segments and no LE command, the controller will stop motion instantly at the last vector. There will be no controlled deceleration. LM? or _LM returns the available spaces for LI segments that can be sent to the buffer. 511 returned means the buffer is empty and 511 LI segments can be sent. A zero means the buffer is full and no additional segments can be sent. As long as the buffer is not full, additional LI segments can be sent at PC bus speeds. The instruction _CS returns the segment counter. As the segments are processed, _CS increases, starting at zero. This function allows the host computer to determine which segment is being processed.

Additional Commands

The commands VS n, VA n, and VD n are used to specify the vector speed, acceleration and deceleration. The DMC-21x2/21x3 computes the vector speed based on the axes specified in the LM mode. For example, LM ABC designates linear interpolation for the A,B and C axes. The vector speed for this example would be computed using the equation: VS2 =AS2 +BS2 +CS2 , where AS, BS and CS are the speed of the A,B and C axes. The controller always uses the axis specifications from LM, not LI, to compute the speed. VT is used to set the S-curve smoothing constant for coordinated moves. The command AV n is the ‘After Vector’ trippoint, which halts program execution until the vector distance of n has been reached.

Specifying Vector Speed for Each Segment

The instruction VS has an immediate effect and, therefore, must be given at the required time. In some applications, such as CNC, it is necessary to attach various speeds to different motion segments. This can be done by two functions: < n and > m For example: LI a,b,c,d < n >m The first command, < n, is equivalent to commanding VSn at the start of the given segment and will cause an acceleration toward the new commanded speeds, subject to the other constraints. The second function, > m, requires the vector speed to reach the value m at the end of the segment. Note that the function > m may start the deceleration within the given segment or during previous segments, as needed to meet the final speed requirement, under the given values of VA and VD.

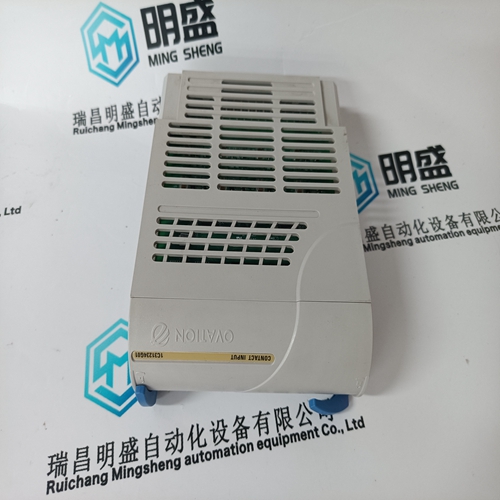

Temporal Ming sheng automation equipment co., LTD., specialized in (DCS system) (robotic system) (large) servo control system (PLC system) module for spare parts sales, inventory adequate, product quality, let you have no trouble back at home of our main products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on

Brand advantage

GE gas turbine electric, ABB, Bently, Emerson, Honeywell, ICS Triplex, WOODWARD , FOXBORO, SST, HIMA , Motorola, TRICONEX invensys,SCHNEIDER A - B, Prosoft import module in Europe and America and so on