Home > Product > Gas turbine system > IC693CMM321 Gas turbine module

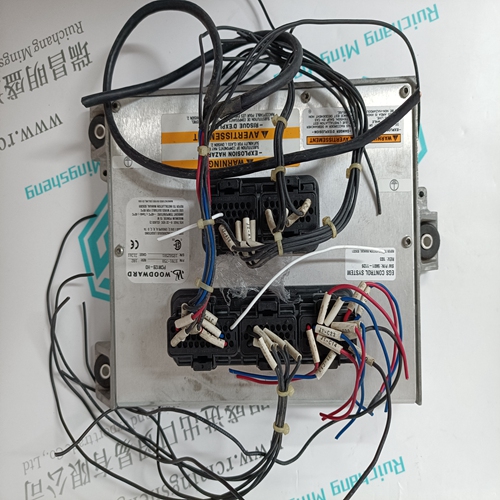

IC693CMM321 Gas turbine module

- Product ID: IC693CMM321

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:IC693CMM321Gas turbine module

- Get the latest price:Click to consult

IC693CMM321 Gas turbine module

This mode allows up to 8 axes to be electronically geared to some master axes. The masters may rotate in both directions and the geared axes will follow at the specified gear ratio. The gear ratio may be different for each axis and changed during motion. The command GA ABCDEFGH specifies the master axes. GR a,b,c,d specifies the gear ratios for the slaves where the ratio may be a number between +/-127.9999 with a fractional resolution of .0001. There are two modes: standard gearing and gantry mode. The gantry mode is enabled with the command GM. GR 0,0,0,0 turns off gearing in both modes. A limit switch or ST command disable gearing in the standard mode but not in the gantry mode. The command GM a,b,c,d select the axes to be controlled under the gantry mode. The parameter 1 enables gantry mode, and 0 disables it.

GR causes the specified axes

to be geared to the actual position of the master. The master axis is commanded with motion commands such as PR, PA or JG. When the master axis is driven by the controller in the jog mode or an independent motion mode, it is possible to define the master as the command position of that axis, rather than the actual position. The designation of the commanded position master is by the letter, C. For example, GACA indicates that the gearing is the commanded position of A. An alternative gearing method is to synchronize the slave motor to the commanded vector motion of several axes performed by GAS. For example, if the A and B motor form a circular motion, the C axis may move in proportion to the vector move. Similarly, if A,B and C perform a linear interpolation move, W can be geared to the vector move. Electronic gearing allows the geared motor to perform a second independent or coordinated move in addition to the gearing. For example, when a geared motor follows a master at a ratio of 1:1, it may be advanced an additional distance with PR, or JG, commands, or VP, or LI.

Ramped Gearing

In some applications, especially when the master is traveling at high speeds, it is desirable to have the gear ratio ramp gradually to minimize large changes in velocity on the slave axis when the gearing is engaged. For example if the master axis is already traveling at 1,000,000 cts/sec and the slave will be geared at a ratio of 1:1 when the gearing is engaged, the slave will instantly develop following error,and command maximum current to the motor.

Temporal Ming sheng automation equipment co., LTD., specialized in (DCS system) (robotic system) (large) servo control system (PLC system) module for spare parts sales, inventory adequate, product quality, let you have no trouble back at home of our main products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on

Brand advantage

GE gas turbine electric, ABB, Bently, Emerson, Honeywell, ICS Triplex, WOODWARD , FOXBORO, SST, HIMA , Motorola, TRICONEX invensys,SCHNEIDER A - B, Prosoft import module in Europe and America and so on