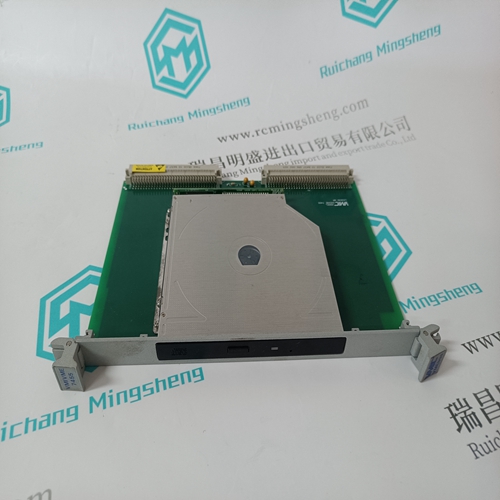

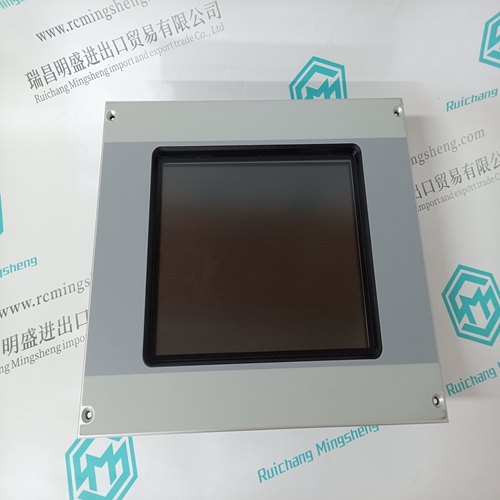

Home > Product > PLC programmable module > BENTLY 133442-01 Monitoring module

BENTLY 133442-01 Monitoring module

- Product ID: 133442-01

- Brand: BENTLY

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:BENTLY133442-01Monitoring module

- Get the latest price:Click to consult

BENTLY 133442-01 Monitoring module

This can be a large shock to the system. For many applications it is acceptable to slowly ramp the engagement of gearing over a greater time frame. Galil allows the user to specify an interval of the master axis over which the gearing will be engaged. For example, the same master X axis in this case travels at 1,000,000 counts/sec, and the gear ratio is:1, but the gearing is slowly engaged over 30,000 cts of the master axis, greatly diminishing the initial shock to the slave axis. Figure 1 below shows the velocity vs. time profile for instantaneous gearing. Figure 2 shows the velocity vs. time profile for the gradual gearing engagement.

The slave axis for each figure

is shown in the bottom portion of the figure; the master axis is shown in the top portion. The shock to the slave axis will be significantly less in figure 2 than in figure1. The ramped gearing does have one consequence. There isn’t a true synchronization of the two axes, until the gearing ramp is complete. The slave will lag behind the true ratio during the ramp period. If exact position synchronization is required from the point gearing is initiated, then the position must be commanded in addition to the gearing. The controller keeps track of this position phase lag with the _GP operand. The following example will demonstrate how the command is used.

Example – Electronic Gearing Over a Specified Interval

Objective Run two geared motors at speeds of 1.132 and -.045 times the speed of an external master. Because the master is traveling at high speeds, it is desirable for the speeds to change slowly. Solution: Use a DMC-1730 or DMC-1830 controller where the Z-axis is the master and X and Y are the geared axes. We will implement the gearing change over 6000 counts (3 revolutions) of the master axis.Answer: In the next example titled Electronic Gearing gearing would take effect immediately. From the start of gearing if the master traveled 6000 counts, the slaves would travel 6792 counts and 270 counts. Using the ramped gearing, the slave will engage gearing gradually. Since the gearing is engaged over the interval of 6000 counts of the master, the slave will only travel ~3396 counts and ~135 counts respectively. The difference between these two values is stored in the _GPn operand. If exact position synchronization is required, the IP command is used to adjust for the difference.

Temporal Ming sheng automation equipment co., LTD., specialized in (DCS system) (robotic system) (large) servo control system (PLC system) module for spare parts sales, inventory adequate, product quality, let you have no trouble back at home of our main products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on

Brand advantage

GE gas turbine electric, ABB, Bently, Emerson, Honeywell, ICS Triplex, WOODWARD , FOXBORO, SST, HIMA , Motorola, TRICONEX invensys,SCHNEIDER A - B, Prosoft import module in Europe and America and so on