Home > Product > DCS control system > 1X00024H01 WH1-2FF Power supply module

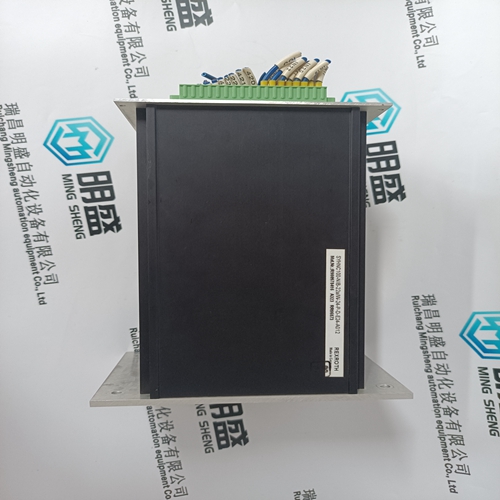

1X00024H01 WH1-2FF Power supply module

- Product ID: 1X00024H01 WH1-2FF

- Brand: EMERSON

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:1X00024H01WH1-2FFPower supply module

- Get the latest price:Click to consult

1X00024H01 WH1-2FF Power supply module

In applications where both the master and the follower are controlled by the DMC-21x2/21x3 controller, it may be desired to synchronize the follower with the commanded position of the master, rather than the actual position. This eliminates the coupling between the axes which may lead to oscillations. For example, assume that a gantry is driven by two axes, A and B, on both sides. This requires the gantry mode for strong coupling between the motors. The A-axis is the master and the B-axis is the follower.

In the electronic cam mode, the position of the master is always expressed modulo one cycle. In this example, the position of x is always expressed in the range between 0 and 6000. Similarly, the slave position is also redefined such that it starts at zero and ends at 1500. At the end of a cycle when the master is 6000 and the slave is 1500, the positions of both a and bare redefined as zero. To specify the master cycle and the slave cycle change, we use the instruction EM.

Electronic Cam

The electronic cam is a motion control mode which enables the periodic synchronization of several axes of motion. Up to 7 axes can be slaved to one master axis. The master axis encoder must be input through a main encoder port. The electronic cam is a more general type of electronic gearing which allows a table-based relationship between the axes. It allows synchronizing all the controller axes. For example, the DMC-2182 controller may have one master and up to seven slaves. To illustrate the procedure of setting the cam mode, consider the cam relationship for the slave axis B, when the master is A. Such a graphic relationship is shown in Figure 6.4. Step 1. Selecting the master axis The first step in the electronic cam mode is to select the master axis. This is done with the instruction

where A is the master with a cycle of 2000 counts.

The cam table can be constructed manually, point by point, or automatically by a program. The following program includes the set-up. The instruction EAA defines A as the master axis. The cycle of the master is 2000. Over that cycle, B varies by 1000. This leads to the instruction EM 2000,1000. Suppose we want to define a table with 100 segments. This implies increments of 20 counts each. If the master points are to start at zero, the required instruction is EP 20,0. The following routine computes the table points. As the phase equals 0.18A and A varies in increments of 20, the phase varies by increments of 3.6°. The program then computes the values of B according to the equation and assigns the values to the table with the instruction ET[N] = ,B.

Temporal Ming sheng automation equipment co., LTD., specialized in (DCS system) (robotic system) (large) servo control system (PLC system) module for spare parts sales, inventory adequate, product quality, let you have no trouble back at home of our main products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on

Brand advantage

GE gas turbine electric, ABB, Bently, Emerson, Honeywell, ICS Triplex, WOODWARD , FOXBORO, SST, HIMA , Motorola, TRICONEX invensys,SCHNEIDER A - B, Prosoft import module in Europe and America and so on