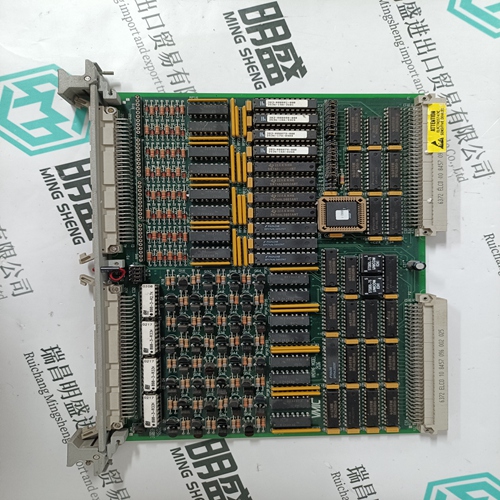

Home > Product > DCS control system > KJ3241X1-BK1 12P4710X032 SE4006P2 module

KJ3241X1-BK1 12P4710X032 SE4006P2 module

- Product ID: KJ3241X1-BK1 12P4710X032 SE4006P2

- Brand: EMERSON

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:KJ3241X1-BK112P4710X032SE4006P2module

- Get the latest price:Click to consult

KJ3241X1-BK1 12P4710X032 SE4006P2 module

The Galil controller can be set into the Stepper Position Maintenance (SPM) mode to handle the event of stepper motor position error. The mode looks at position feedback from the main encoder and compares it to the commanded step pulses. The position information is used to determine if there is any significant difference between the commanded and the actual motor positions. If such error is detected, it is updated into a command value for operator use. In addition, the SPM mode can be used as a method to correct for friction at the end of a microstepping move. This capability provides closedloop control at the application program level. SPM mode can be used with Galil and non-Galil step drives. SPM mode is configured, executed, and managed with seven commands. This mode also utilizes the #POSERR automatic subroutine allowing for automatic user-defined handling of an error event.

When a Galil controller is configured for step motor operation

the step pulse output by the controller is internally fed back to the auxiliary encoder register. For SPM the feedback encoder on the stepper will connect to the main encoder port. Enabling the SPM mode on a controller with YS=1 executes an internal monitoring of the auxiliary and main encoder registers for that axis or axes. Position error is then tracked in step pulses between these two registers (QS command).Where TD is the auxiliary encoder register(step pulses) and TP is the main encoder register(feedback encoder). Additionally, YA defines the step drive resolution where YA = 1 for full stepping or YA = 2 for half stepping. The full range of YA is up to YA = 9999 for microstepping drives.

Error Limit

The value of QS is internally monitored to determine if it exceeds a preset limit of three full motor steps. Once the value of QS exceeds this limit, the controller then performs the following actions: 1. The motion is maintained or is stopped, depending on the setting of the OE command. If OE=0 the axis stays in motion, if OE=1 the axis is stopped. 2. YS is set to 2, which causes the automatic subroutine labeled #POSERR to be executed.

Temporal Ming sheng automation equipment co., LTD., specialized in (DCS system) (robotic system) (large) servo control system (PLC system) module for spare parts sales, inventory adequate, product quality, let you have no trouble back at home of our main products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on

Brand advantage

GE gas turbine electric, ABB, Bently, Emerson, Honeywell, ICS Triplex, WOODWARD , FOXBORO, SST, HIMA , Motorola, TRICONEX invensys,SCHNEIDER A - B, Prosoft import module in Europe and America and so on