Home > Product > PLC programmable module > FLN3524A CPU3640 Control card

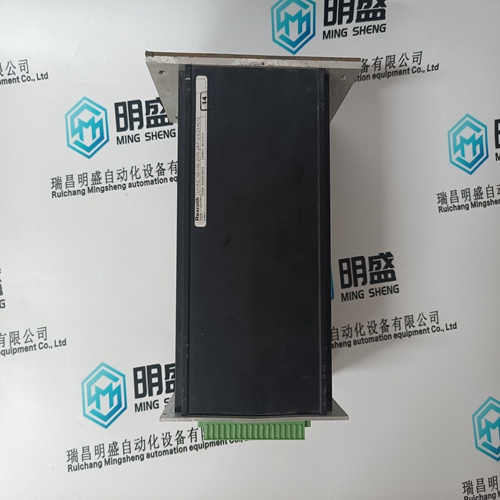

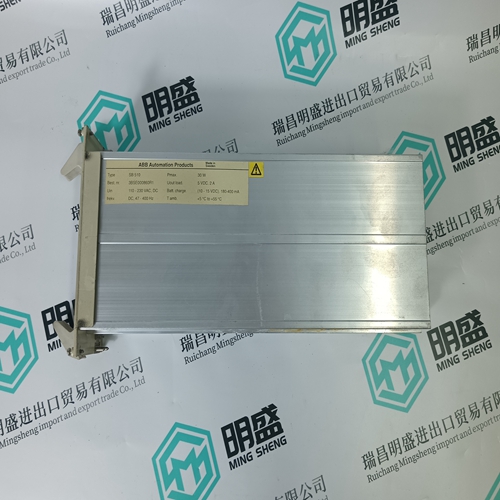

FLN3524A CPU3640 Control card

- Product ID: FLN3524A CPU3640

- Brand: MOTOROLA

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:FLN3524ACPU3640Control card

- Get the latest price:Click to consult

FLN3524A CPU3640 Control card

The second method, the sampled dual loop, reads the load encoder only at the end point and performs a correction. This method is independent of the size of the backlash. However, it is effective only in point-to-point motion systems which require position accuracy only at the endpoint.

The DMC-21x2/21x3 controller allows the smoothing of the velocity profile to reduce the mechanical vibration of the system. Trapezoidal velocity profiles have acceleration rates which change abruptly from zero to maximum value. The discontinuous acceleration results in jerk which causes vibration. The smoothing of the acceleration profile leads to a continuous acceleration profile and reduces the mechanical shock and vibration.

Continuous Dual Loop

Connect the load encoder to the main encoder port and connect the motor encoder to the dual encoder port. The dual loop method splits the filter function between the two encoders. It applies the KP (proportional) and KI (integral) terms to the position error, based on the load encoder, and applies the KD (derivative) term to the motor encoder. This method results in a stable system.Note that the dual loop compensation depends on the backlash magnitude, and in extreme cases will not stabilize the loop. The proposed compensation procedure is to start with KP=0, KI=0 and to maximize the value of KD under the condition DV1. Once KD is found, increase KP gradually to a maximum value, and finally, increase KI, if necessary

Sampled Dual Loop

In this example, we consider a linear slide which is run by a rotary motor via a lead screw. Since the lead screw has a backlash, it is necessary to use a linear encoder to monitor the position of the slide. For stability reasons, it is best to use a rotary encoder on the motor. Connect the rotary encoder to the A-axis and connect the linear encoder to the auxiliary encoder of A. Assume that the required motion distance is one inch, and that this corresponds to 40,000 counts of the rotary encoder and 10,000 counts of the linear encoder. The design approach is to drive the motor a distance, which corresponds to 40,000 rotary counts. Once the motion is complete, the controller monitors the position of the linear encoder and performs position corrections.

Temporal Ming sheng automation equipment co., LTD., specialized in (DCS system) (robotic system) (large) servo control system (PLC system) module for spare parts sales, inventory adequate, product quality, let you have no trouble back at home of our main products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on

Brand advantage

GE gas turbine electric, ABB, Bently, Emerson, Honeywell, ICS Triplex, WOODWARD , FOXBORO, SST, HIMA , Motorola, TRICONEX invensys,SCHNEIDER A - B, Prosoft import module in Europe and America and so on