Home > Product > PLC programmable module > PROSOFT MVI56-MDA4 Communication module

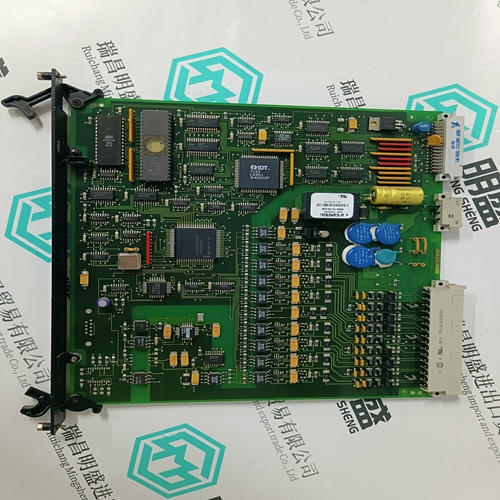

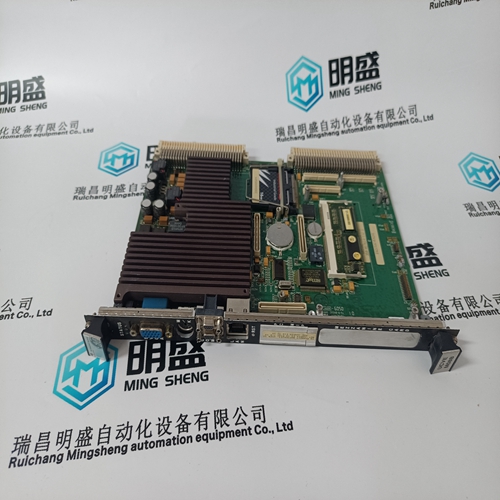

PROSOFT MVI56-MDA4 Communication module

- Product ID: MVI56-MDA4

- Brand: PROSOFT

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:PROSOFTMVI56-MDA4Communication module

- Get the latest price:Click to consult

PROSOFT MVI56-MDA4 Communication module

The Home (HM) command can be used to position the motor on the index pulse after the home switch is detected. This allows for finer positioning on initialization. The command sequence HM and BG causes the following sequence of events to occur.

1. Upon begin, motor accelerates to the slew speed. The direction of its motion is determined by the state of the homing input. A zero (GND) will cause the motor to start in the forward direction; +5V will cause it to start in the reverse direction. The CN command is used to define the polarity of the home input.

2. Upon detecting the home switch changing state, the motor begins decelerating to a stop.

3. The motor then traverses very slowly back until the home switch toggles again.

4. The motor then traverses forward until the encoder index pulse is detected.

5. The DMC-21x2/21x3 defines the home position (0) as the position at which the index was detected.

High Speed Position Capture (The Latch Function)

Often it is desirable to capture the position precisely for registration applications. The DMC21x2/21x3 provides a position latch feature. This feature allows the position of the main or auxiliary encoders of A,B,C or D to be captured when the latch input changes state. This function can be set up such that the position is captured when the latch input goes high or low. With the standard TTL inputs, the latch time is less than 1 microsecond. Optoisolation is available for the controller through the ICM-20105 or the ICM-20500. When the latch function is enabled for active low operation, the position will be captured within 12 microseconds. With optoisolation, when the latch function is enabled for active high operation, the position will be captured within 35 microseconds.

The DMC-21x2/21x3 software commands

AL and RL, are used to arm the latch and report the latched position. The steps to use the latch are as follows: 1. Give the AL ABCD command to arm the latch for the main encoder and ALSASBSCSD for the auxiliary encoders. 2. Test to see if the latch has occurred (Input goes low) by using the _AL A or B or C or D command. Example, V1=_ALA returns the state of the A latch into V1. V1 is 1 if the latch has not occurred. 3. After the latch has occurred, read the captured position with the RL ABCD command or _RL ABCD. NOTE: The latch must be re-armed after each latching event.

Temporal Ming sheng automation equipment co., LTD., specialized in (DCS system) (robotic system) (large) servo control system (PLC system) module for spare parts sales, inventory adequate, product quality, let you have no trouble back at home of our main products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on

Brand advantage

GE gas turbine electric, ABB, Bently, Emerson, Honeywell, ICS Triplex, WOODWARD , FOXBORO, SST, HIMA , Motorola, TRICONEX invensys,SCHNEIDER A - B, Prosoft import module in Europe and America and so on