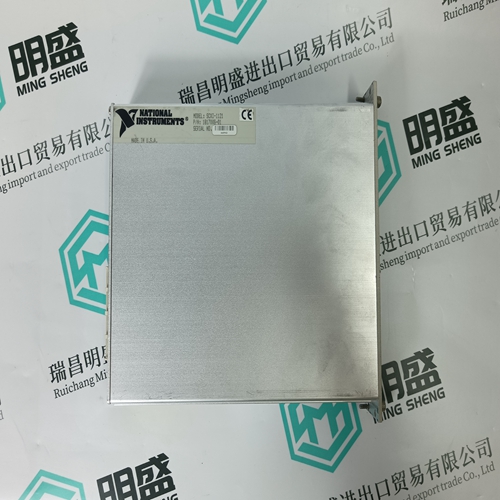

Home > Product > PLC programmable module > NI SCXI-1141 Low pass filter, input mold piece

NI SCXI-1141 Low pass filter, input mold piece

- Product ID: SCXI-1141

- Brand: NI

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:NISCXI-1141Low pass filterinput mold piece

- Get the latest price:Click to consult

NI SCXI-1141 Low pass filter, input mold piece

Eight channels for SCXI ellipse low-pass filtering device input module - SCXI ‑ 1141 is a programmable filter cheng mold piece, is the ideal choice of the anti aliasing application. Although all the same cut-off frequency channel must be set, but you can make cheng let alone one channel of low pass filtering signal around. Analog filter device and switched capacitor filter device, the combination of not only provides 10000 discrete software programmable routine cutoff frequency for users to choose freely, while maintaining the traditional continuous time of active filter low noise performance.

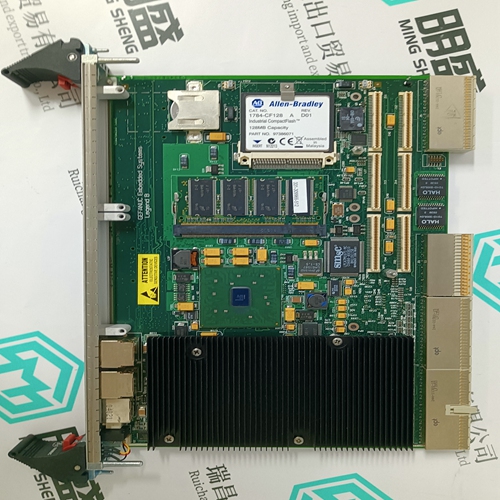

Extended I/O of the DMC-21x2/21x3 Controller

The DMC-21x2/21x3 controller, with optional DB-28040, offers 40 extended I/O points which can be configured as inputs or outputs in 8 bit increments through software. The I/O points are accessed through the daughter board, which utilizes one 50-pin IDC ribbon connectors. Configuring the I/O of the DMC-21x2/21x3 The 40 extended I/O points of the DMC-21x2/21x3 series controller can be configured in blocks of 8. The extended I/O is denoted as blocks 2-6 or bits 17-56. The command, CO, is used to configure the extended I/O as inputs or outputs. The CO command has one field: CO n where n is a decimal value which represents a binary number. Each bit of the binary number represents one block of extended I/O. When set to 1, the corresponding block is configured as an output. The least significant bit represents block 2 and the most significant bit represents block 9.

Accessing Extended I/O

When configured as an output, each I/O point may be defined with the SBn and CBn commands (where n=1 through 8 and 17 through 56). Outputs may also be defined with the conditional command, OBn (where n=1 through 8 and 17 through 56). The command, OP, may also be used to set output bits, specified as blocks of data. The OP command accepts 5 parameters. The first parameter sets the values of the main output port of the controller (Outputs 1-8, block 0). The additional parameters set the value of the extended I/O as outlined: OP m,a,b,c,d

Saving the State of the Outputs in Non-Volatile Memory

The configuration of the extended I/O and the state of the outputs can be stored in the EEPROM with the BN command. If no value has been set, the default of CO 0 is used (all blocks are inputs).

Temporal Ming sheng automation equipment co., LTD., specialized in (DCS system) (robotic system) (large) servo control system (PLC system) module for spare parts sales, inventory adequate, product quality, let you have no trouble back at home of our main products are widely used in metallurgy, petroleum, glass, aluminum manufacturing, petrochemical industry, coal mine, papermaking, printing, textile printing and dyeing, machinery, electronics, automobile manufacturing, tobacco, plastics machinery, electric power, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution and so on

Brand advantage

GE gas turbine electric, ABB, Bently, Emerson, Honeywell, ICS Triplex, WOODWARD , FOXBORO, SST, HIMA , Motorola, TRICONEX invensys,SCHNEIDER A - B, Prosoft import module in Europe and America and so on