Home > Product > DCS control system > 193X532ADG04 on-site control board

193X532ADG04 on-site control board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

193X532ADG04 on-site control board

Product Details Introduction

Introduction to GE 193X532ADG04 Field Control Board

GE 193X532ADG04 is one of the on-site control modules in the 193X series control system launched by General Electric, mainly used in early GE industrial drive systems and process automation control systems. This module is commonly used in regulating and feedback control circuits, suitable for DC/AC motor control, power generation excitation, and automatic operation control of large equipment.

Technical specifications and functional features

Control type: Analog signal processing control board with certain logical control capability

Input signals: voltage input, analog feedback signal, digital control signal, etc

Output signal: an analog signal or logic control quantity used to control power modules, execution units, and drive boards

Installation method: Standard GE plug-in card structure, inserted into the motherboard backplane

Power requirement: Typically ± 15V DC (supplied uniformly through the system)

Onboard components: including multiple potentiometers, discrete circuit components, operational amplifiers, etc

Status feedback: Some versions may be equipped with status indicator lights for running status judgment or debugging support

Adjustable parameters: such as gain (GAIN), offset (OFFSET), response time, etc., can be adjusted through potentiometers

application area

GE Mark series industrial automation systems (such as Mark I, II, IV, etc.)

DC motor excitation control and speed regulation system

Industrial furnace control, metallurgical continuous casting, rolling line drive system

Excitation device and frequency conversion control circuit of power plant

Replacement parts requirements in maintenance and renovation projects for old industrial equipment

Key points for use and maintenance

Before installation, the power must be turned off to avoid arcing or damage to the interface during plugging and unplugging operations.

Anti static operation standards require wearing an electrostatic ring when in contact with the board to avoid electrostatic breakdown of the device.

Signal inspection: Use a multimeter or oscilloscope to check if the input and output voltage/waveform are normal.

Regular maintenance: Focus on checking whether the electrolytic capacitor is swollen, whether the connectors are oxidized, and whether there are cracks in the solder joints.

Parameter adjustment: If you need to adjust the control effect, it is recommended to fine tune the onboard potentiometer under the guidance of the original equipment manual.

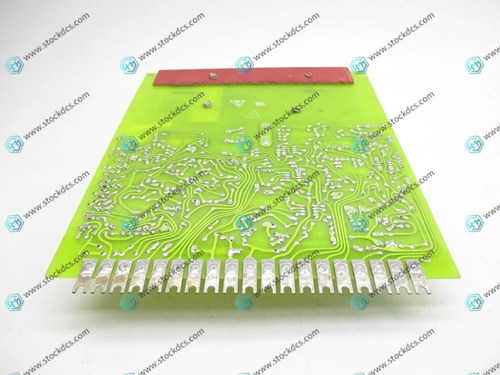

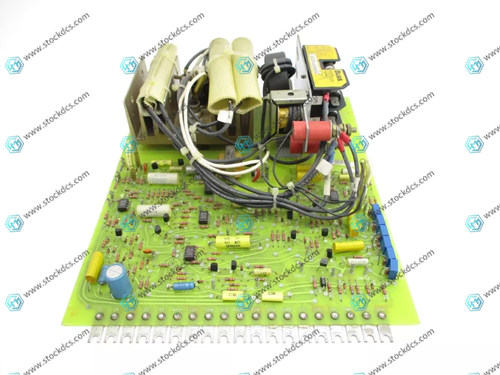

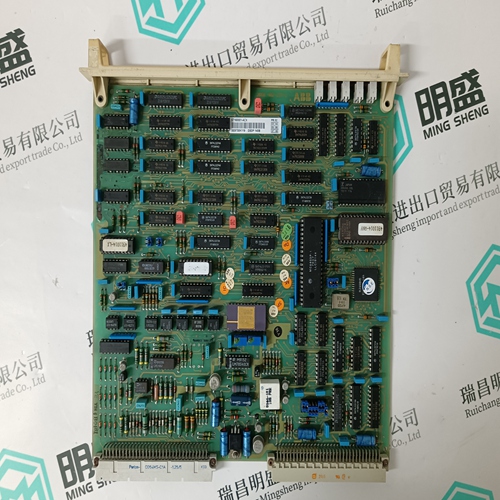

Product imag

Related website links

ABB SB822 3BSE018172R1 rechargeable

CI860K01 3BSE032444R1 power module

CI871AK01 3BSE092693R1 interface module

Other website links

ABB CHBX01R 2VAA008575R1 冗余模块底座

| PMA44P-00100-00 | AMAT 0100-35213 | PFTL 101AER-2.0KN |

| PMA44N-01100-00 | AMAT 0100-14003 | PFTL 301E-0.2 |

| PMA43R-10100-00 | AMAT 0100-35279 | PFTL 101AE-1.0KN |

| PMA43Q-Y0100-02 | AMAT 0100-77043 | PFTC 101X |

| PMA43Q-10100-00 | AMAT 0100-00060 | PFEA113-65 3BSE050092R65 |

| PMA43Q-00100-00 | AMAT 0100-00059 | PFTL101A-0.5KN 3BSE004166R1 |

| PMA43P-11100-00 | ANAT 0100-76091 | PFEA113 |

| PMA43P-10100-00 | AMAT 0100-00985 | PFTL 201D-100.0KN |