Home > Product > PLC programmable module > 193X543ABG02 electric circuit board

193X543ABG02 electric circuit board

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:

- Get the latest price:Click to consult

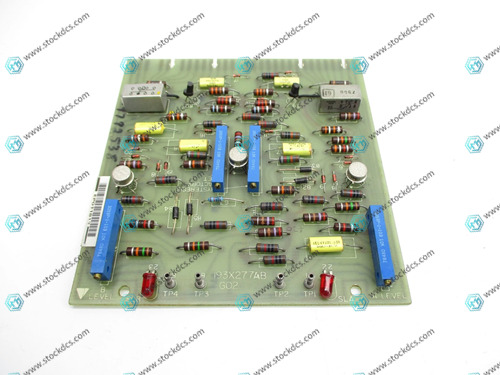

193X543ABG02 electric circuit board

Product Details Introduction

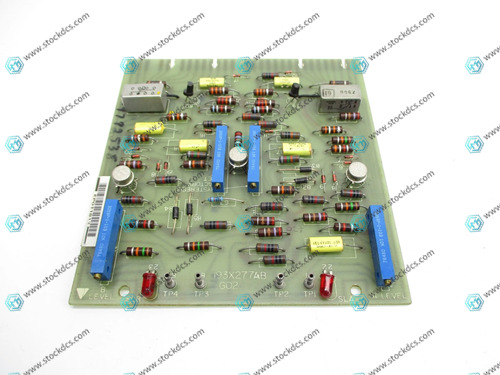

GE 193X543ABG02 is a critical circuit board in General Electric's 193X series industrial control systems, often referred to as an "electric control board" or "electric circuit board". This module is widely used in GE's DC or AC drive systems to execute control logic for electric equipment, including motor drive signal processing, feedback regulation, system protection, and other functions.

This circuit board is usually used as a sub functional board of the entire drive system, working together with the main control board, feedback board, excitation board, etc., to ensure the stable operation of the equipment on the industrial site.

Technical parameters and functional characteristics

Model: 193X543ABG02

Product type: Motor Control PCB

System adaptation: GE 193X series industrial automation system

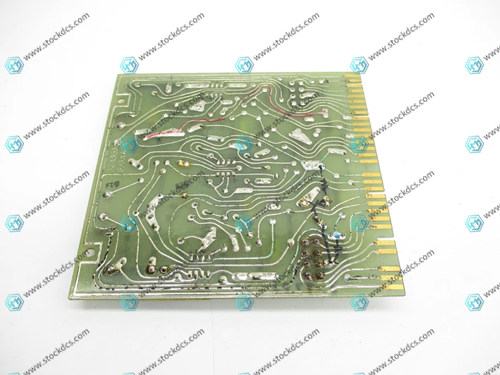

Installation method: Standard card insertion installation, connected to the control framework through a gold finger interface

Input signals: analog signals (such as voltage feedback, current feedback), digital logic commands, trigger control signals

Output signal: Control signal output to actuators, drivers, relays, etc

Onboard components: integrated with multiple operational amplifiers, transistors, adjustable potentiometers, capacitors, resistors, and other standing element devices

Adjustment function: Equipped with a potentiometer for adjusting control gain, response time, compensation parameters, etc

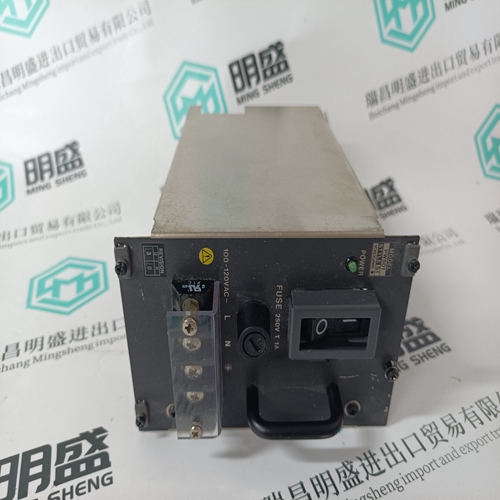

Working voltage: usually ± 15V DC, requiring unified power supply from the system

Working temperature range: -20 ℃ to+70 ℃, suitable for industrial site environment

Status display: Some versions come with LED status indicators for easy debugging and operation monitoring

Application scenarios

GE Mark series industrial motor control system (such as Mark II, IV)

Large DC/AC motor drive equipment

Process control industries such as metallurgy, petrochemicals, power plants, water treatment, pulp and paper manufacturing, etc

Used to perform tasks such as motor start stop control, speed regulation, and status feedback processing

It is often used in the replacement or expansion of electric daughter boards in old GE control systems

Installation and usage precautions

Before installation, the system power must be disconnected to avoid short circuits or arcs during plugging and unplugging operations

The board is a static sensitive device, and an anti-static wristband should be worn during operation

All input and output signals should be strictly connected according to the system design drawings to prevent control logic abnormalities

Before the initial operation, a multimeter and oscilloscope can be used to check the voltage waveform and level of key test points

If the potentiometer needs to be adjusted, it should be slowly adjusted and the initial setting should be recorded in order to roll back the debugging value

It is recommended to conduct maintenance checks every 6-12 months, with a focus on issues such as capacitor aging, loose solder joints, and interface contact

Product imag

Related website links

KJ3222X1-BA1 Analog Input Module

Siemens 6ES7307-1EA01-0AA0 power module

Other website links

ABB UFC933A102 3BHE048062R0102 电路板

| PMA42N-00100-00 | AMAT 0100-00611 | PFTL 301E-0.5 |

| PMA42M-10100-00 | AMAT 0100-02797 | PFTL 301E-0.1 |

| PMA42M-01100-00 | AMAT 0100-14005 | PFTL 101BE-10.0KN |

| PMA42M-00100-00 | AMAT 0100-35082 | PFEA112-IP20 3BSE030369R0020 |

| PMA24K-1050B-02 | AMAT 0100-90139 | PFTL 101A-1.0KN |

| PMA24D-10100-00 | AMAT 0100-00642 | PFTL 301E-1.0KN |

| PMA24D-00100-00 | AMAT 0100-09292 | PFTL101A 1.0KN |

| PMA24C-11100-00 | AMAT 0100-00069 | PFTL 101BE-20.0KN |

| PMA24C-10100-00 | AMAT 0100-35170 | PFTL 101BER-10.0KN |