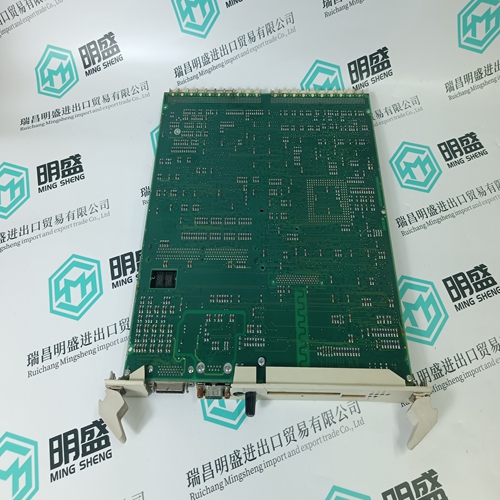

Home > Product > DCS control system > 1C31192G01 Digital output module

1C31192G01 Digital output module

- Product ID: 1C31192G01

- Brand: EMERSON

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:1C31192G01Digital output module

- Get the latest price:Click to consult

1C31192G01 Digital output module

differently than they are in Normal mode. In Pass-Through mode, all write requests will be passed directly to the processor and data will not be written directly into the database. This mode is especially useful whenever both a Modbus Master and the module’s processor logic need to be able to read and write values to the same internal database addresses. The following diagram shows the data flow for a slave port with pass-through enabled:.During normal backplane communications, the data from the Write Data array, including the data updated by the Pass-Through Write Block, is sent to the module’s internal database. This gives the ladder logic the opportunity to also change the values stored in these addresses, if need be, before they are written to the database.

Same as normal mode.

a. In Pass-Through mode, if the slave driver receives a read request, it looks for the data in module’s internal database, just as it would in Normal mode. b. The data needed to respond to the read command is retrieved directly from the internal database and returned to the Slave driver so it can build a response message. c. In Pass-Through mode if the slave driver receives a write request, it does not send the data directly to the module’s internal database. It puts the data to be written into a special Input Image with special Block ID code to identify it as a Pass-Through Write Block and substitutes this speical block in place of the next regular Read Data Block. The special block is processed by the ladder logic and the data to be written is placed into the controller tag WriteData array at an address that corresponds to the Modbus Address received in the write command.

Master Driver Mode

In the Master mode, the MVI69-MCM module issues read or write commands to slave devices on the MODBUS network. These commands are user configured in the module via the Master Command List is received from the user defined configuration file that is stored on the MVI69-MCM module or can be issued directly from the CompactLogix or MicroLogix processor (Special Command Blocks). Command status is returned to the processor for each individual command in the command list. The location of this command status list in the module’s internal database is user defined. The following flow chart and associated table describe the flow of data into and out of the module.

1.Payment method and delivery

Shipment: EMS,DHL,UPS & FEDEX

Payment: T/T or Western Union

2. About us

We are professional company and we are expert in this business, we have highly experienced production team, or sales team, or purchase team, we have most advanced production line. We are reputable in the market.

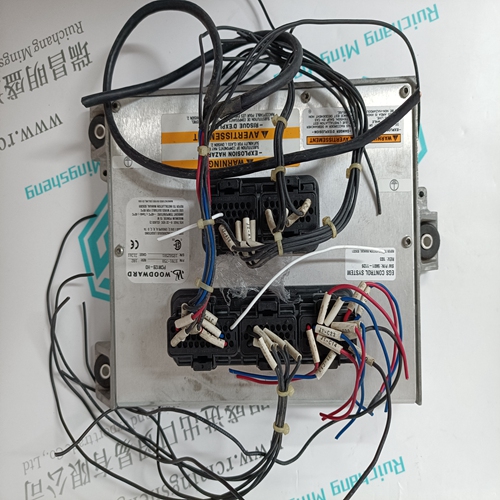

3. Application industry

Our main products are widely used in metallurgy, oil and gas, glass manufacturing, aluminum, petrochemical, coal mine, paper making and printing, textile printing and dyeing, machinery, electronic manufacturing, automobile manufacturing, tobacco, plastic machinery, electricity, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution, etc.