Home > Product > DCS control system > ABB UAD 206 A101 3BHE019959P201 processing module

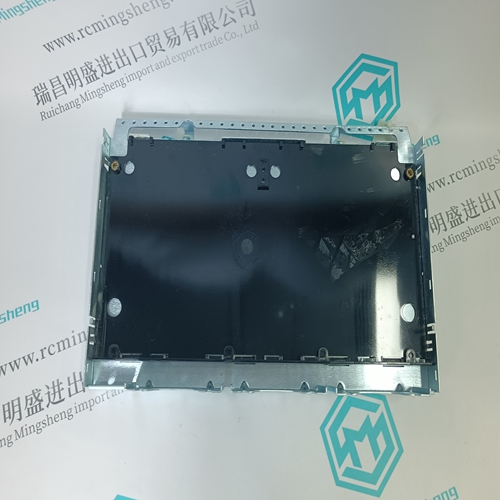

ABB UAD 206 A101 3BHE019959P201 processing module

- Product ID: UAD 206 A101 3BHE019959P201

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBUAD 206 A1013BHE019959P201processing module

- Get the latest price:Click to consult

ABB UAD 206 A101 3BHE019959P201 processing module

If a signal generator is used set the signal for the frequency of the speed sensor at rated speed, and connect it to terminals 7 and 8. (The rated speed frequency in Hz equals the rated engine speed in RPM times the number of teeth on the speed sensing gear, times the ratio of engine speed to speedsensing-gear speed, divided by 60.) Put the Close For Rated contact in rated (closed) position. Set the speed trim potentiometer (if used) to midposition. Connect a dc analog voltmeter to terminals 9 (+) and 10 (–) to read actuator voltage. If the actuator voltage is at minimum (about 0 volts) slowly turn the RATED SPEED potentiometer clockwise (counterclockwise for reverse acting controls) until the voltage just begins to move toward maximum. If the actuator voltage is at maximum, slowly turn the RATED SPEED potentiometer counterclockwise (clockwise for reverse-acting controls) until the voltage just begins to move toward minimum.

Continue to very slowly adjust the RATED SPEED

potentiometer in the appropriate direction, trying to stop the actuator voltage between the minimum and maximum voltages. Because it is not possible to stop the motion, cease adjusting when the voltage changes very slowly. The RATED SPEED potentiometer is now set very close to the desired speed. A slight adjustment when the engine is running will achieve the exact speed.Be prepared to make an emergency shutdown when starting the engine, turbine, or other type of prime mover, to protect against runaway or overspeed with possible personal injury, loss of life, or property damage.

Check the speed sensor

Minimum voltage required from the speed sensor to operate the electronic control is 1.0 Vrms, measured at cranking speed or the lowest controlling speed. For this test, measure the voltage while cranking, with the speed sensor connected to the control. Before cranking, be sure to prevent the prime mover from starting. At 5% of the lower value of the control's speed range, the failed speed sensing circuit is cleared. For example 100 Hz is required on the 2000 to 6000 Hz speed range (2000 Hz x .05 = 100 Hz).

Superior products

We mainly make spare parts for DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: professional off production accessories,

Fast delivery, accurate delivery time,

Main brands include ABB, GE/FANC, FOXBORO, TRICONEX, BENTLY NEVADA, A-B, EMERSON, OVATION, MOTOROLA, XYVOM, HONEYWELL, REXROTH, KUKA, NI, DEIF, Reliance Electric, Yokogawa, WOODWARD, SCHNEIDER, MOOG, PROSOFT and other brands