Home > Product > Servo control system > WOODWARD 9907-838 digital speed governor

WOODWARD 9907-838 digital speed governor

- Product ID: 9907-838

- Brand: WOODWARD

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:WOODWARD9907-838digital speed governor

- Get the latest price:Click to consult

WOODWARD 9907-838 digital speed governor

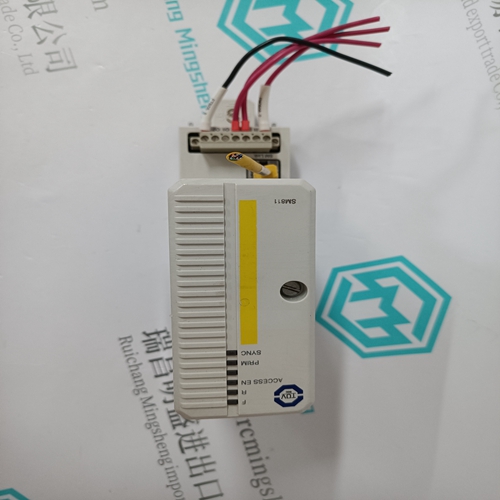

Location Considerations Consider these requirements when selecting a mounting location for the SPC: Adequate ventilation for cooling Space for servicing and repair Protection from direct exposure to water Protection from high-voltage or high-current devices, or devices which produce electromagnetic interference Avoidance of vibration Selection of a location that will provide an operating temperature range of (–40 to +70) °C / (–40 to +158) °F This product is intended for installation in an enclosed industrial control cabinet. In order to meet the requirements for Zone 2 Hazardous Location, the SPC must be mounted in an enclosure with ingress protection of IP54 or greater.

Optional SPC Mounting Kit

Optionally, SPC mounting bracket kit #8928-7334 is available for use in reducing required panel mounting space within a cabinet. Ideal for applications where multiple SPCs are utilized, this bracket allows SPCs to be mounted such that they protrude vertically into the cabinet, reducing the required panel mounting area. This bracket’s design allows users to first attach the SPC to the bracket, then install the entire assembly onto a cabinet side panel. Please refer to Figure 2-1

Shields and Grounding

A shield termination is provided at the terminal block for each of the signals. All of these inputs should be wired using shielded, twisted-pair wiring. The exposed wire length beyond the shield should be limited to one 25 mm (1 inch). The shield should be terminated at only one end in order to avoid creating a ground loop.The SPC chassis must be connected to PE Ground (Potential Earth) using the grounding lug. The wire used for PE ground must be the same size used for the input wires. The SPC must be attached to protective earth by a ground strap or otherwise, and all cables shielded to ensure electromagnetic immunity integrity. For best noise immunity, power cables should be run in separate cable trays or conduits from the low-level I/O cables.

Superior products

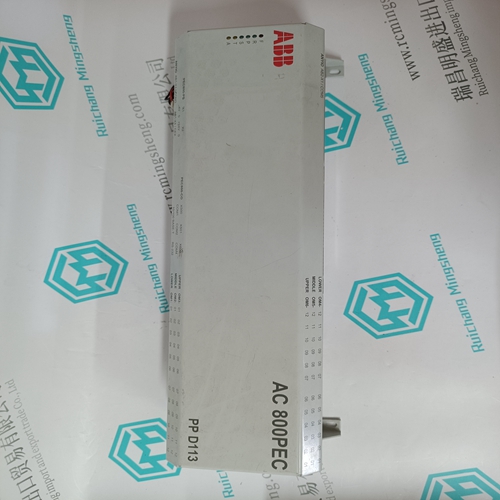

We mainly make spare parts for DCS, PLC, robot control system and large servo system.

Main products: various modules/cards, controllers, touch screens, servo drives.

Advantages: professional off production accessories,

Fast delivery, accurate delivery time,

Main brands include ABB, GE/FANC, FOXBORO, TRICONEX, BENTLY NEVADA, A-B, EMERSON, OVATION, MOTOROLA, XYVOM, HONEYWELL, REXROTH, KUKA, NI, DEIF, Reliance Electric, Yokogawa, WOODWARD, SCHNEIDER, MOOG, PROSOFT and other brands