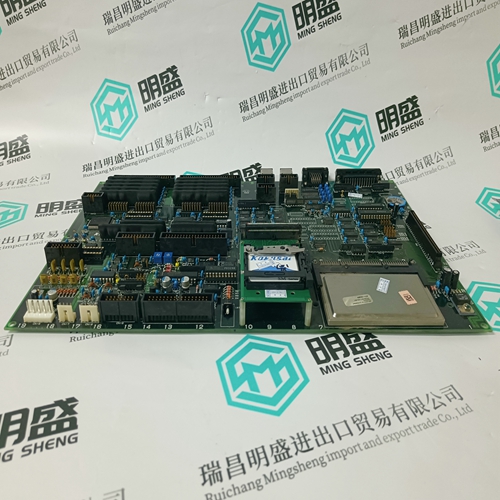

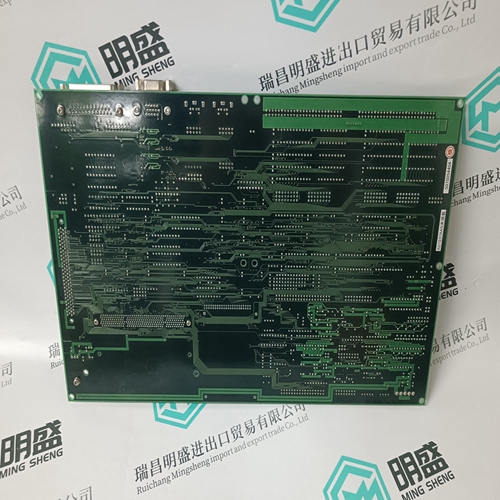

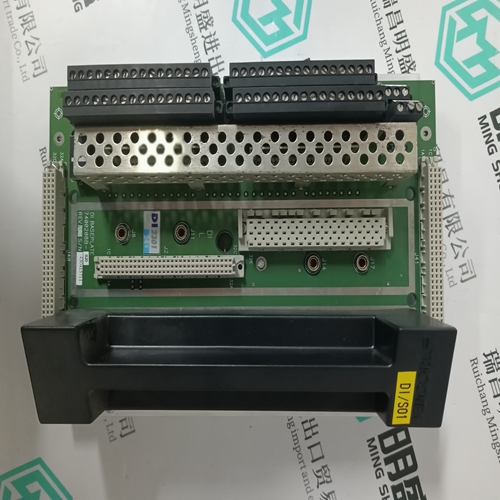

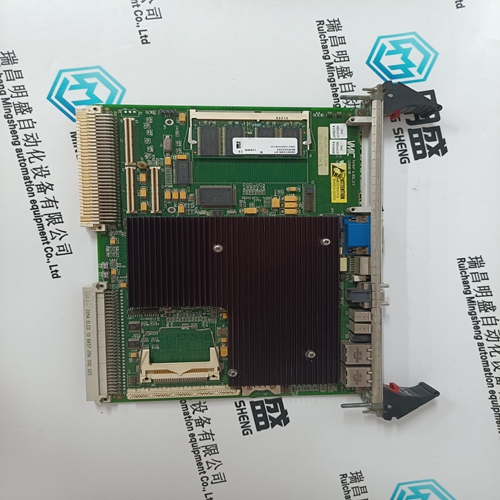

Home > Product > Robot control system > KOKUSAI CXP-544A KOMS-A2 Main control circuit board

KOKUSAI CXP-544A KOMS-A2 Main control circuit board

- Product ID: CXP-544A KOMS-A2

- Brand: KOKUSAI

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:KOKUSAICXP-544A KOMS-A2Main control circuit board

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

KOKUSAI CXP-544A KOMS-A2 Main control circuit board

A coincidence output is always active and does not require a start or stop signal. If the weight on the scale is below the target minus the spill value, the outputs are “on”. If the weight is above the target minus the spill value, the outputs are “off”. This type of output typically requires external logic to provide the required control for feeding systems This describes the operation of the feed output in a 2-speed feeding system. If the feeder type is programmed as concurrent, both the fast feed and feed outputs are active at the beginning of a target comparison. When the weight reaches the point at which a slower feed is to occur, the fast feed output is turned off. This refers to the physical output connection that is used for the faster feed in a 2-speed feeding system. This output is not used in a single speed feeding system This refers to the physical output connection that is used for the slower feed in a 2-speed feeding system or the only feed output in a single speed feeding system The value entered for the amount of material that will be fed in the slower rate of feed in a 2-speed feeding system. This value and the spill value are subtracted from the target to determine the point that the fast feed output turns off

Target Comparison

Target comparison is used to compare either the gross or net weight on the scale to a predetermined target value. This feature can be useful in both automatic and manual processes. As an example, an automatic filling system using target comparison could provide a Start signal to the IND780 and the IND780 could control the feeder system to fill a container to a desired target. An example of a manual process could be a checkweighing station where an operator is checking net weight of packages. The IND780 can use its target comparison feature to provide a graphical Over - OK - Under indication to help the operator determine if the weight of each package is acceptable or not compared to an ideal weight. Target (setpoint) comparison is most often used in two types of applications: • Material transfer applications—Requires that a control device deactivate when a target value is achieved • Over/Under applications—Classify a load placed on the scale platform as above or below the target value or within the target tolerance range The IND780 target comparison rate (for analog load cell scales) is 50 comparisons per second. The comparison rate for high precision IDNet bases depends on the module in the base. See the IND780 Technical Manual, Chapter 3.0, Configuration, the Application section, Memory, Target Table and Operation, Target for further information about configuring parameters for target comparison operations.