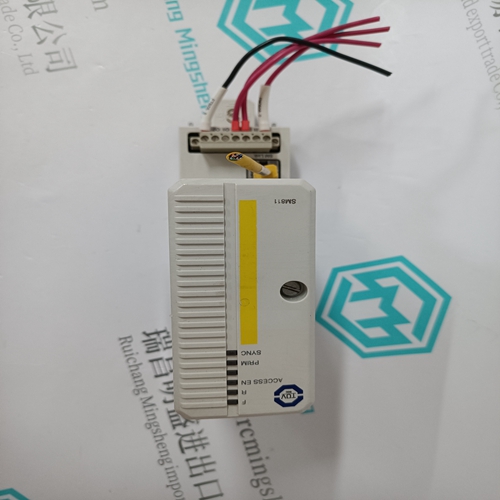

Home > Product > Robot control system > EATON DPM-MC2 Main communication module

EATON DPM-MC2 Main communication module

- Product ID: DPM-MC2

- Brand: EATON

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:EATONDPM-MC2Main communication module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

EATON DPM-MC2 Main communication module

This describes the operation of the feed output in a 2-speed feeding system. If the feeder type is programmed as independent, the feed output does not turn on until the fast feed output turns off. Only one feeder output is active at a time. It is the opposite of concurrent outputs.Latched outputs turn off at the target weight minus the spill value and remain off (regardless of additional plus or minus weight changes) until a “start” signal is received. These types of outputs do not usually require external logic to perform standard weigh-in or weighout sequences.The target comparison mode that provides control for delivering a measured amount of material from one container or vessel to another. The transfer can apply to material entering or leaving a container or vessel. It covers applications traditionally using terms such as weigh-in, weigh-out, filling, and dosing.

After a target comparison process has been paused, it may be resumed by pressing the Resume softkey or by triggering a discrete input programmed as Target Start/Resume. When a target comparison is resumed, it continues to use the original target values. Spill The amount of material that will be added (on a weigh-in) or removed (on a weigh-out) from the scale after the final feed is turned off. In a weigh-in process, this is the material in suspension that will still fall onto the scale when the feed is turned off. This value is subtracted from the target value to determine when the feed output turns off.

Target Control

Two different levels of target control are provided by the terminal for the Material Transfer mode. Latching outputs must be enabled to utilize either type of automated control. For simple applications, no control is provided. The comparison runs at all times. Whenever the scale weight is less than the target value, the output is True/enabled. For those applications where latching outputs are used or more control is needed for an occasional pause or to abort a comparison process, the TARGET CONTROL softkey is used. Pressing the TARGET CONTROL softkey provides a dedicated display for the target comparison with the comparison status and appropriate softkeys shown. Possible status modes are “Ready”, “Running” or “Paused”. The appropriate control softkeys include START , PAUSE , and STOP . Target control functionality does not work when coincidence targets are configured.Over/Under Applications If the target comparison of the IND780 will be used to checkweigh the weight of a product, the application can be classified as an Over/Under application. These types of applications are usually manual processes but can also be automated. The SmartTrac display indicates the classification of the weight placed on the scale and discrete I/O can be used to trigger external lights or other controls. The terminal compares the current weight to a previously entered target with tolerance values, or to zone limits; it then indicates the results. In HTable 2-6 definitions will explain some terms used in Over/Under applications, and are specific to those applications