Home > Product > DCS control system > ABB DSSA165 48990001-LY control module

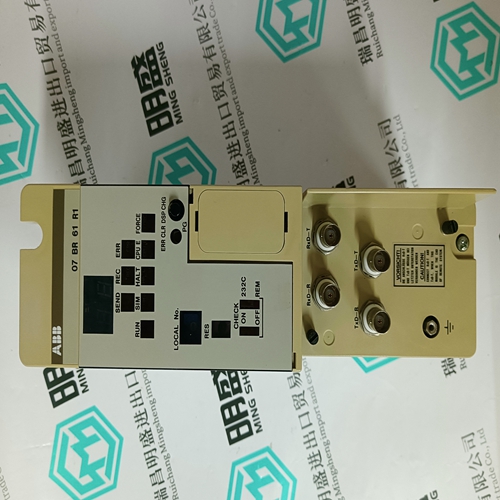

ABB DSSA165 48990001-LY control module

- Product ID: DSSA165 48990001-LY

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBDSSA16548990001-LYcontrol module

- Get the latest price:Click to consult

ABB DSSA165 48990001-LY control module

Determining power dissipation

⇒ See the motor documentation for the continuous current at standstill IdN (see "MKD Digital AC Motors"- Project Planning -).

⇒ Using the IdN value of the motor selected, find the value in the diagram in Fig. 10-1 for the power dissipation PV, DKC.

⇒ Convert the continuous regenerative power found in Tab. Fig. 3-2 with the factor 0.8. as bleeder-dependent power dissipation PV, Bleeder in the DKC.

⇒ Add both dissipation values (PV,DKC and PV,Bleeder). Use the total (PV,ges) for planning the control cabinet.

Using heat-exchange units in the control cabinets

Improperly installed and operated heat-exchange units are a risk to the drive components installed in the control cabinet due to the condensation and condensed water which these may cause! Humid air enters the cabinet and, as it cools, condenses onto the installed drive components. If the heat-exchange unit is not properly installed in the control cabinet, accumulating condensing water can drip into the installed drive components or be sprayed into them by the cold air current.

Avoiding condensation

Proper use of the heat-exchange units: • When using heat heat-exchange units, the cabinets must be well sealed so that moisture cannot form caused by humid outside air entering the cabinets! • In the event that the control cabinets are operated with open doors (startup operation, servicing, etc.), ensure that the drive components are never cooler than the air in the control cabinets after the doors have been closed. Otherwise, condensation may occur. For this reason, it is important that the heat-exchange unit continues to operate when the system has been shut down to ensure that temperature within the control cabinet does not deviate from that of the drive components.

Superior products

Main products include DCS control system spare parts, PLC system spare parts and robot system spare parts,

Advantage brands: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, B&R, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft and other imported industrial parts

Application industry

Our main products are widely used in metallurgy, oil and gas, glass manufacturing, aluminum, petrochemical, coal mine, paper making and printing, textile printing and dyeing, machinery, electronic manufacturing, automobile manufacturing, tobacco, plastic machinery, electricity, water conservancy, water treatment/environmental protection, municipal engineering, boiler heating, energy, power transmission and distribution, etc.