Home > Product > DCS control system > CMA136 3DDE300416 Industrial module

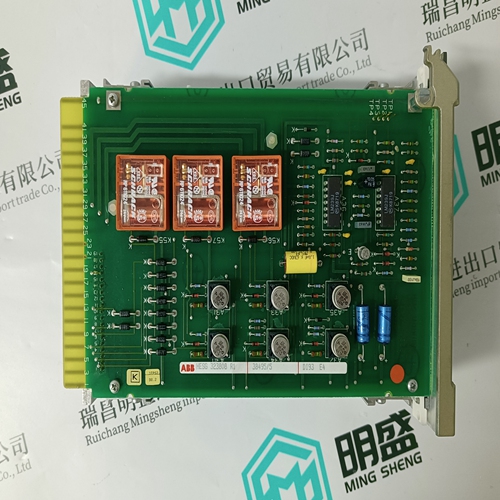

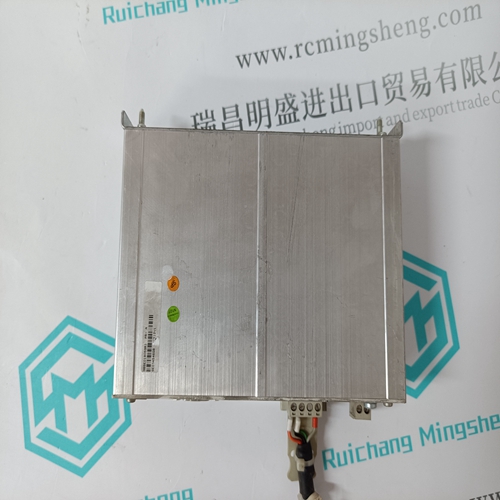

CMA136 3DDE300416 Industrial module

- Product ID: CMA136 3DDE300416

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:CMA136 3DDE300416Industrial module

- Get the latest price:Click to consult

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

CMA136 3DDE300416 Industrial module

The GE Multilin PQMII Power Quality Meter is an ideal choice for continuous monitoring of a single or three-phase system. It provides metering for current, voltage, real power, reactive power, apparent power, energy use, cost of power, power factor, and frequency. Programmable setpoints and four assignable output relays allow control functions to be added for specific applications. This includes basic alarm on over/under current or voltage, unbalance, demand-based load shedding, and capacitor power factor correction control. More complex control is possible using the four switch inputs; these can also be used for status information such as breaker open/closed and flow information. As a data gathering device for plant automation systems that integrate process, instrument, and electrical requirements, all monitored values are available via one of two RS485 communication ports running the Modbus protocol. If analog values are required for direct interface to a PLC, any of the monitored values can output as a 4 to 20 mA (or 0 to 1 mA) signal to replace up to four (4) separate transducers. A third RS232 communication port connects to a PC from the front panel for simultaneous access of information by other plant personnel. With increasing use of electronic loads such as computers, ballasts, and variable frequency drives, the quality of the power system is important. With the harmonic analysis option, any phase current or voltage can be displayed and the harmonic content calculated. Knowledge of the harmonic distribution allows action to be taken to prevent overheated transformers, motors, capacitors, neutral wires, and nuisance breaker trips. Redistribution of system loading can also be determined. The PQMII can also provide waveform and data printouts to assist in problem diagnosis.

Feature Highlights

• Monitoring: A, V, VA, W, var, kWh, kvarh, kVAh, PF, Hz • Demand metering: W, var, A, VA • Setpoints for alarm or control from most measured values, including: unbalance, frequency, power factor, voltage, and current • four (4) output relays / four (4) switch inputs for flexible control configuration • four (4) isolated analog outputs replace transducers for PLC interface • one 4 to 20 mA analog input • Modbus communications • Three COM ports (two rear RS485 ports and one front RS232 port) for access by process, electrical, maintenance, and instrument personnel • Harmonic analysis for power quality review and problem correction • 40-character display and keypad for local programming • No-charge EnerVista PQMII Setup Software • Simulation mode for testing and training • Compact design for panel mount • AC/DC control power 1.1.3 Applications of the PQMII • Metering of distribution feeders, transformers, generators, capacitor banks, and motors • Medium and low voltage three-phase systems • Commercial, industrial, utility • Flexible control for demand load shedding, power factor, etc. • Power quality analysis • System debugging