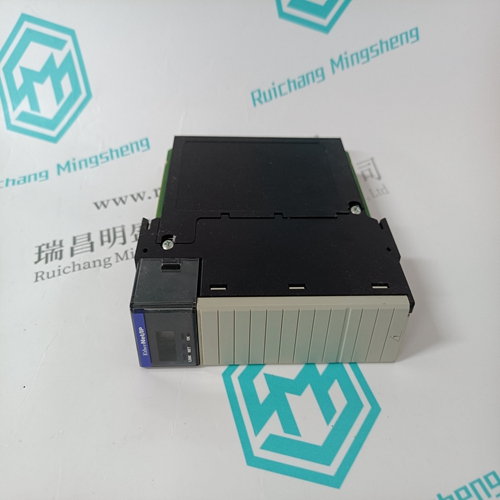

Home > Product > Robot control system > MICRO XV-440-10TVB-1-10 Touch screen

MICRO XV-440-10TVB-1-10 Touch screen

- Product ID: XV-440-10TVB-1-10

- Brand: MICRO

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:MICROXV-440-10TVB-1-10Touch screen

- Get the latest price:Click to consult

MICRO XV-440-10TVB-1-10 Touch screen

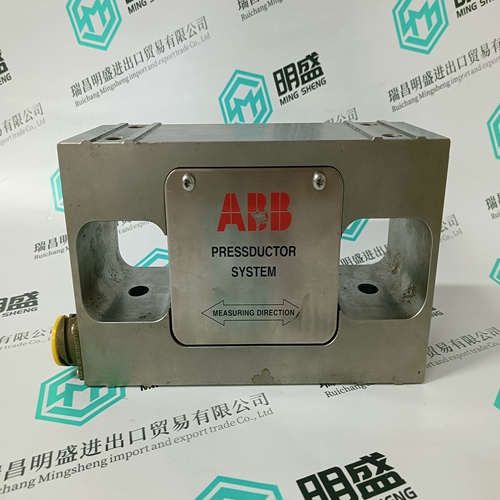

Local operation and monitoring is carried out via the operation unit or M/A control stations. In the case of increased demands on the availability of critical control loops, M/A control stations can be used in addition to the operation unit of the automation system as an alternative to a redundant AS 235 H CPU. In the event of a fault in the central processor, these loops can then be accessed and monitored from the control room. Remote control of motors, actuators, solenoid values and controllers is possible directly from the central control room using M/A control stations provided a process enable is present and if no protection commands exist. The operation can also be made dependent on a manual enable in the control room. The M/A control stations are connected to the closed–loop and open–loop control modules via serial interfaces. The maximum permissible distance between the M/A control station and the associated module is 900 m.

The M/A control stations are fitted in desks or panels.

If the AS 235 system is used in stand–alone mode without coupling to other AS automation systems, process operation and monitoring are carried out using the operation unit. This unit consists of a process operation keyboard and a process monitor. Messages and logs are output on a printer. Two independent operation units, each with a message printer and a logging printer, can be connected to an AS 235 automation system. The maximum permissible distance between an operation unit and the automation system is 150 m.

Central operation and monitoring

Central operation and monitoring is carried out using an OS 520 or OS 265–3 operation and monitoring system which is connected to several automation systems via the CS 275 bus system. Such an operation and monitoring system can be used to carry out the complete process control of large plants from a central point. Local operation units can be used redundant to the operation and monitoring systems or combined with them. There are no limitations or interlocks whatsoever between the operation and monitoring systems and the operation unit. The OS 520 and OS 265–3 operation and monitoring systems use a light pen (OS 265–3 only), mouse or touch screen for process control, or optionaly their own process operation keyboard (OS 265–3 only).

after-sale service

Focus on sales of imported industrial automation equipment

1 year professional warranty service

Our large inventory contains current and outdated products in the automation industry, if you are looking for new leftovers Products. We are knowledgeable and friendly about all outdated and legacy automation, our remaining products or discontinued parts Our internal team tests each part before delivery. Good colleagues can help you get what you need,All parts sold by AMIKON are actually in stock. With our competitive prices, we will This makes emergency transportation a solution to emergency shutdown. Haodi provides you with the necessary parts inventory A simple solution to the situation.