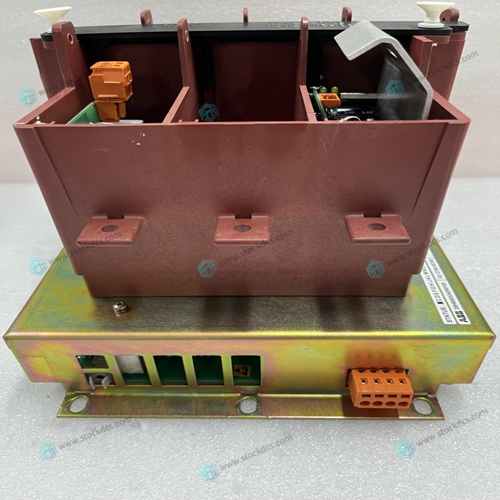

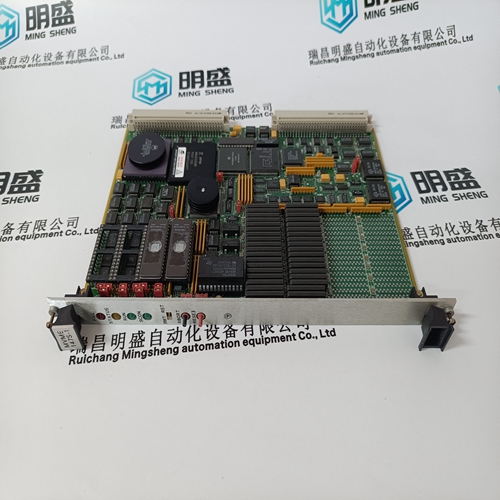

Home > Product > DCS control system > ABB 3BHB005243R0105 KUC755AE105 Excitation module

ABB 3BHB005243R0105 KUC755AE105 Excitation module

- Product ID: 3BHB005243R0105 KUC755AE105

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABB3BHB005243R0105KUC755AE105Excitation module

- Get the latest price:Click to consult

ABB 3BHB005243R0105 KUC755AE105 Excitation module

There are 5 levels for different processing (selectable with ZYK,cycleno). According to the level– specific processing sequence, all inserted blocks are activated in start status (operator input “STA”). Operator input “STO” disables all user block processing (exception: cf GB.ORPA.232). The system configuration functions are not affected by this operation.Central faults (I&C alarms) are directly output in the VDU message line, on the printer and via the bus subsystem. The fault is stored in a block–specific manner, which suppresses the cyclic output of the same fault message. The fault display is enabled after an operator input “QF”; or “QF;...:” (cf. Chapter 5.1.5), and all waiting or occurring faults will be indicated again. The I&C alarms (internal alarms or received via the bus subsystem) may be output via one of four printers. A GE operator input can be used to suppress the output (cf. Chapters 5.1.3).

After a display has been ouput

values can be entered for operator–controllable blocks. Operator inputs are output as operator messages via a selected printer (operator input GE,...;) or via the bus subsystem. Operator messages received by the bus subsystem are printed on the same device as internal messages. GE can be entered to suppress the output. Messages from MEL blocks received by the bus subsystem are logged on a device selected via a GE entry. A GE entry can also be used to suppress MEL outputs. Blocks with status messages store the current status in a system interface, which is processed in a 125–ms cycle. Waiting status messages are transferred to the bus subsystem. One message may contain up to seven status messages

A watchdog function is started every 125 ms on the first I/O bus interface.

The cabinet lamp will light up if any I&C alarms have occurred. The cabinet lamp is a 1–min. cycle. Permanent faults prevent the cabinet lamp from being extinguished. At least one fault alarm is present within the system if the cabinet lamp is on (operator input QF). Status such as “open door” or “overtemperature” are monitored and indicated in a one–second cycle. Standard devices, such as process communication keyboard, configuration keyboard, printer can be replaced or disconnected from the interface module at any time. The system checks every 8 seconds (GA.ORPA.26) if these devices have been reconnected or the printers issue a ready signal. If a standard device becomes inoperable, an I&C alarm is issued.

after-sale service

Focus on sales of imported industrial automation equipment

1 year professional warranty service

Our large inventory contains current and outdated products in the automation industry, if you are looking for new leftovers Products. We are knowledgeable and friendly about all outdated and legacy automation, our remaining products or discontinued parts Our internal team tests each part before delivery. Good colleagues can help you get what you need,All parts sold by AMIKON are actually in stock. With our competitive prices, we will This makes emergency transportation a solution to emergency shutdown. Haodi provides you with the necessary parts inventory A simple solution to the situation.