Home > Product > PLC programmable module > NI PXI-6528 Matrix switch module

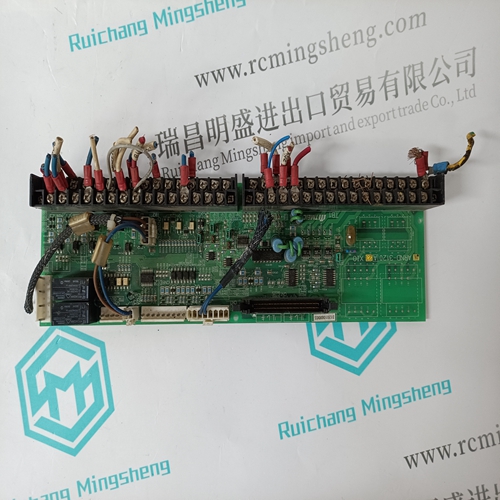

NI PXI-6528 Matrix switch module

- Product ID: PXI-6528

- Brand: NI

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:NIPXI-6528Matrix switch module

- Get the latest price:Click to consult

NI PXI-6528 Matrix switch module

Structured charts as task specification for TML blocks The structured chart, which has been internationally accepted, is a graphical representation of a logic sequence. It forces the programmer to “structured programming”, i.e. it allows less errors than the unstructured flow charts previously used. Structured charts consist of a small amount of simple module pictures.Theoretically, it is possible to have as many nestings or concatenations as required (only 10 nestings with TML). This permits representation of any block size – systematically subdivided into individual modules. Each block can be used directly (1:1) as a TML instruction.

This means that a structured chart

should be created for each TML block prior to entering the TML lines. Only a structured chart such as this (which does not show any TML/TELEPERM M/SIEMENS characteristics can give a unique and complete description of a specific task. This is also true to converse: If a specific task cannot be represented as a structured chart, the task has not been specified clearly and uniquely. Insufficient specification of the task may lead to difficulties in the assessment for creating a TML block. If a TML block is entered, despite a missing structured chart, the task specification must normally be made up during programming/configuration or during test or commissioning.

Introduction to the Basic Structure of TML User Programs

TML instructions – like configuration instructions for standard function blocks and STEP M instructions – can be used for performing logic operations on data stored in the memory. The logic results are then stored as data in the memory. “Data in the memory” of an AS 235 system merely refers to the names of the memory locations where the binary or analog input or output values (EB, EA, AB, AA, ...) related to previously defined blocks (= data records) have been stored. Each block is associated with a type and has an element number; each input and output inside a block has a number or an element name (cf. data structure definition, EL instruction, Chap. 5.3.1).

Professional service

In industrial automation, if you're looking for a new product or production of remaining parts, our knowledgeable and friendly colleagues can help you gain the required things, with our competitive prices, we will be proud to provide you with the necessary spare parts inventory

Superior products

Main products include DCS control system spare parts, PLC system spare parts and robot system spare parts,

Advantage brands: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, B&R, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft and other imported industrial parts