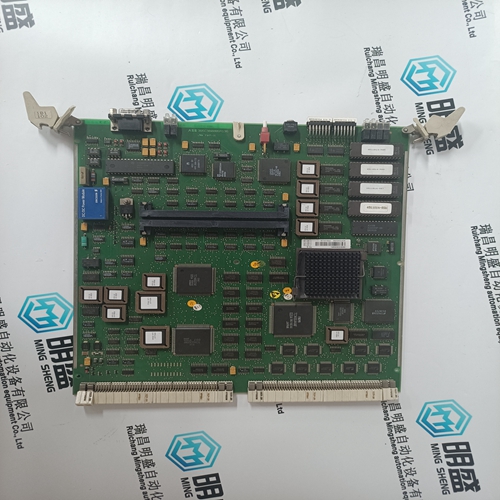

Home > Product > PLC programmable module > NI PXI-6551 Multifunction I/O module

NI PXI-6551 Multifunction I/O module

- Product ID: PXI-6551

- Brand: NI

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:NIPXI-6551Multifunction I/O module

- Get the latest price:Click to consult

NI PXI-6551 Multifunction I/O module

Global operator input check Each instruction given to the system is checked by the standard operator routine which reacts accordingly. Up to now the user had only limited access to the operator input information. A new system interface has been created which allows global reactions to all operator inputs in a project– or user–related fashion. The system checks whether a user–defined PROBLEM called CHECK exists. If it does, the system transfers data specified in the transfer parameters to this PROBLEM. This data is then interpreted by the user who can react as required.

Example: Selecting specific blocks is not permitted. Selection of blocks used for operator–process communication of plant sections according to the operator position. Specific reactions to PBT keys

Initialization blocks

The start–up program of an AS 235 system executes initialization blocks as subroutines in the sequence in which they have been defined (according to the internal block number). Execution is performed after each system start: – Start after battery/power failure NAU/ ZRS – Start after reset operation RSOF – Start after loading a diskette PROBLEM.CHECK runs under the standard operator routine priority. Only short functions should therefore be programmed. PROB.CHECK is called after the operator input has been executed, and has therefore no influence on the operator input.

Call by the User Program Subroutines

The subroutines discussed here are always of the PROBLEM type and do not possess their own data record. They are defined – if a program which is independent of a function block is required; or – if certain identical instruction sequences are repeated frequently in one or various blocks. Here a subroutine is mainly used to save memory space. Like all other programs, PROBLEM blocks have their own set of auxiliary cells (i.e. the auxiliary cell LA1, for example, of the calling block remains unchanged, even if the activated subroutine has changed its internal auxiliary cell LA1 in the meantime). Two different call modes, depending on the two different applications of a PROBLEM block, exist.

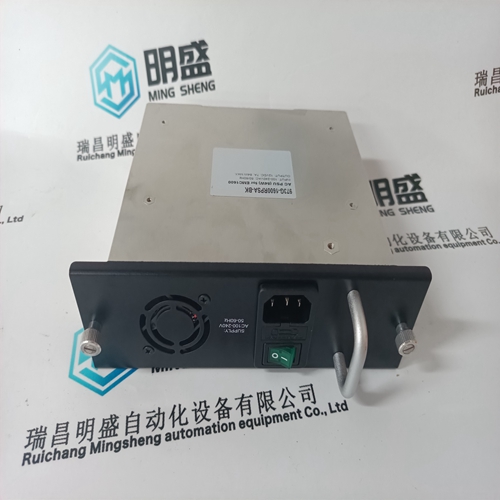

Professional service

In industrial automation, if you're looking for a new product or production of remaining parts, our knowledgeable and friendly colleagues can help you gain the required things, with our competitive prices, we will be proud to provide you with the necessary spare parts inventory

Superior products

Main products include DCS control system spare parts, PLC system spare parts and robot system spare parts,

Advantage brands: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, B&R, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft and other imported industrial parts