Home > Product > PLC programmable module > NI PXI-6608 Transfer switch module

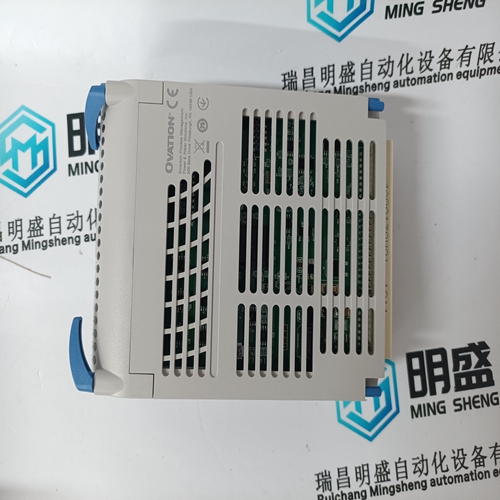

NI PXI-6608 Transfer switch module

- Product ID: PXI-6608

- Brand: NI

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:NIPXI-6608Transfer switch module

- Get the latest price:Click to consult

NI PXI-6608 Transfer switch module

Call via APRO function block The subroutine is interconnected with an APRO function block. In addition, GA/GB/GM/GT data blocks and general data records can be configured (data multiplex technique: cf. STEP/ VS/KS or LAYOUT/BILD/PROT). The APRO block can be installed in a sequence cascade. The subroutine is then called by the APRO block according to the selected cycle and is then supplied with the current data record address. The subroutine is activated by a different program, the main program. Data transfer can be defined by the user, i.e. the subroutine can either retrieve the data to be processed from specified data records, or the data can be transferred using one or various GIVE instructions.

Various RETURN instructions are allowed within one program.

The subroutine is called from the main program by ”name” is a user–defined subroutine name which consists of 4 alphanumeric characters starting with a letter. Up to 4080 subroutines are allowed. As many data items as fit in a TML line can be transferred by a GIVE instruction. Additional GIVE instructions may be given if more data items need to be transferred. The same quantity of receive data must be accepted by the subroutine. A 10–fold nesting of subroutines is possible.The return data need not be mentioned for each RETURN instruction in the subroutine if the TAKE and GIVE instructions have been located together at the program start, i.e. directly after

Any analog or binary data can be used as transfer or receive data.

The data descriptions are separated by commas. The following rule applies: Analog (a) and binary data (b) must be accepted (received) by the associated TAKE instruction in the same order as they were transferred (transmitted) by the GIVE instruction.The meaning and sequence of received and transmitted data must be agreed between the calling and the activated block. The names of received and transmitted data need not be identical.The ’binary accumulator’ must be preset with 1B prior to calling a STEP M program from a TML program. If it is not, the correct function of the STEP M program will depend on the random data in the accumulator at the time when the call is made.

Professional service

In industrial automation, if you're looking for a new product or production of remaining parts, our knowledgeable and friendly colleagues can help you gain the required things, with our competitive prices, we will be proud to provide you with the necessary spare parts inventory

Superior products

Main products include DCS control system spare parts, PLC system spare parts and robot system spare parts,

Advantage brands: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, B&R, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft and other imported industrial parts