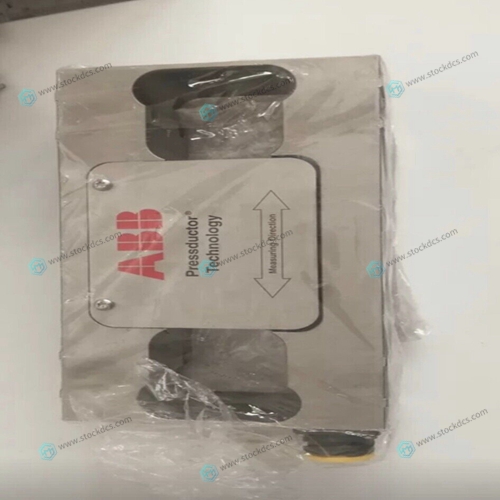

Home > Product > DCS control system > ABB PETL101AER Tension sensor

ABB PETL101AER Tension sensor

- Product ID: PETL101AER

- Brand: ABB

- Place of origin: The Swiss

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:ABBPETL101AERTension sensor

- Get the latest price:Click to consult

ABB PETL101AER Tension sensor

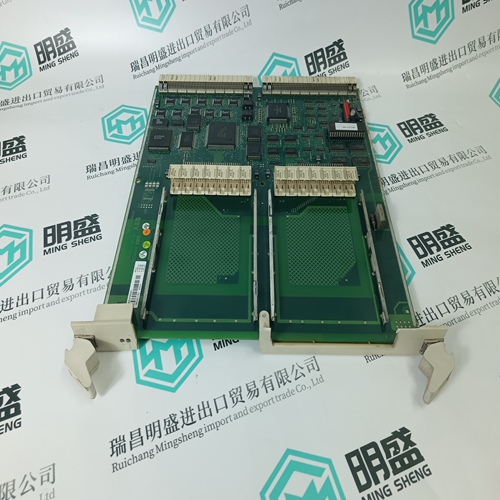

Signalling of I/O Error Messages Signalling of I/O errors distinguishes between

– central unit operational

– central unit not operational

The messages from the I/O module, which is an autonomous monitoring unit, are assigned to the appertaining circuits (measuring circuit, open–loop or closed–loop control circuit). The I/O error messages determined here result in a circuit diagnosis.

CPU Ready I/O error messages initiated by I/O modules are automatically issued – at the module – at the control station – at the individual driver block – on the monitor

Independent of central unit processing

the I/O error messages derived from the monitoring circuitry on the I/O module are issued – as LED indications on the module front panel, – as hardware output (e.g. common alarm) via backplane connector X2 (process interface), – as LED indication on the control station. In addition, the individual I/O error messages are read via the I/O bus when the associated driver block is being processed, and are available as individual driver block binary outputs. The I/O error messages pending at the operator–controllable drivers (e.g. EV, EM, RE...) are output in the respective status word, transferred via the bus and displayed on the operator station monitor as – group message (blinking mark) in the area and group display (as in the event of a process fault alarm), – individual message in the loop display (highest priority).

Signalling on the I/O module

Front panel indication An I/O error message pending in the I/O module is indicated in the diagnosis field on the module front panel (see Fig. 7.43). The diagnosis field – always contains the module fuse and a red LED as common alarm indicator (2 Hz blinking light) – of function modules contains 4 additional red LEDs (a,b,c,d) indicating the I/O error with the highest priority. The individual error types are displayed in coded fashion. The pending error with the highest priority is indicated. The diagnostics of multi–channel function modules (see Fig. 7.44) refer to the circuit selected via the shorting socket and the channel fault LED.

Do you want to know about our products?

We have a large amount of inventory and high quality, out of production control system components, DCS system accessories, robot system accessories, large servo system spare parts. PLC module, DCS module, CPU module, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion control module, analog input module, analog output module, digital input module, digital output module, redundancy module, power module, relay output module, relay input module, processor module and other major brands.