Home > Product > Robot control system > NEC RSA-983/D Vector signal module

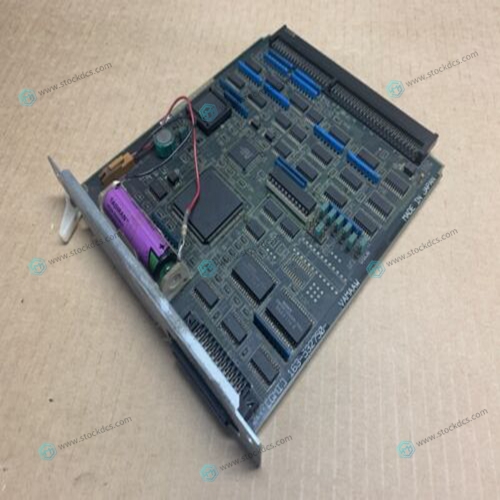

NEC RSA-983/D Vector signal module

- Product ID: RSA-983/D

- Brand: NEC

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:NECRSA-983/DVector signal module

- Get the latest price:Click to consult

NEC RSA-983/D Vector signal module

Solenoid Energizing Solenoids must be held energized for a desired action. Spring offset models have an internal spring which offsets the valve spool when solenoid is de-energized. Notes Any sliding spool valve, if held shifted under pressure for long periods of time, may stick and not spring return due to fluid residue formation, and , therefore, should be cycled periodically to prevent this from happening. Surges of oil in a common tank line serving these and other valves can be of sufficient magnitude to cause inadvertent shifting of the pilot spool of the valves. Separate tank lines or a vented manifold with a continuous downward path to tank are necessary

Application Tank Conditions

The tank connection should be piped directly to tank to minimize back pressure. Any back pressure in the tank line is additive to the valve pressure setting. If tank line back pressure exceeds system pressure by 7 bar (100 psi) a malfunction may occur. Transient pressure peaks in the tank line must not exceed 175 bar (2500 psi). Drain “Y” port must be piped directly to tank through a surge free line such that there will be no back pressure at the valve drain port. Transient pressure must not exceed 0,35 bar

Electrical Service

Solenoids are identified by a letter in the model number. Example: DGC5-060A-C-M-W-B-70 (See chart below for solenoid voltage ratings and coil identification letters.Vickers sequence modular “hydrocushion” type pressure control valves are used to control sequencing of oil flow in hydraulic systems. Control is initiated by a pressure rise which is sensed internally (directly). The valves provide a wiring cavity located in the DG4V pilot valve. A ground terminal is provided as shown.Pressure Setting Must be at least 17 bar (250 psi) lower than the system relief valve setting. Pressure Adjustment Adjust pressure by loosening jam nut and turning adjusting screw. Clockwise rotation increases pressure; counterclockwise rotation decreases pressure

Do you want to know about our products?

We have a large amount of inventory and high quality, out of production control system components, DCS system accessories, robot system accessories, large servo system spare parts. PLC module, DCS module, CPU module, IO module, DO module, AI module, DI module, network communication module, Ethernet module, motion control module, analog input module, analog output module, digital input module, digital output module, redundancy module, power module, relay output module, relay input module, processor module and other major brands.