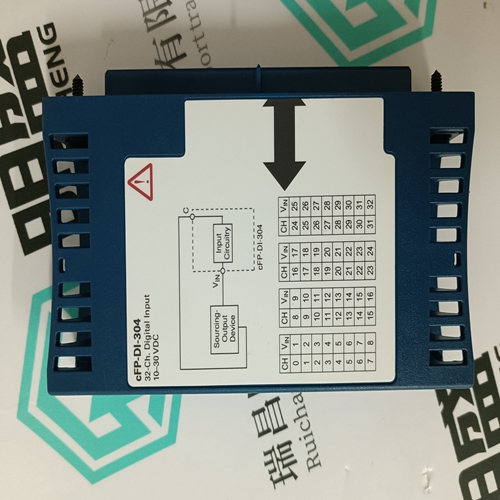

Home > Product > PLC programmable module > NI CFP-DI-304 Digital input module block

NI CFP-DI-304 Digital input module block

- Product ID: CFP-DI-304

- Brand: NI

- Place of origin: the United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:stodcdcs@gmail.com

- Tags:NICFP-DI-304Digital input module block

- Get the latest price:Click to consult

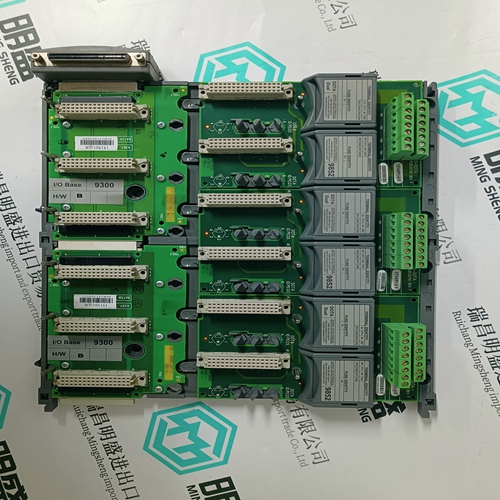

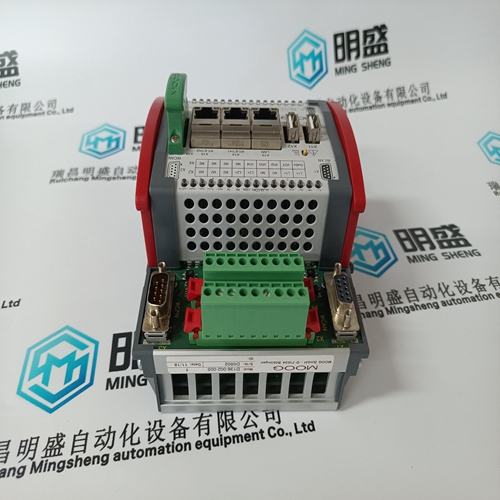

The main products

Spare parts spare parts, the DCS control system of PLC system and the robot system spare parts,

Brand advantage: Allen Bradley, BentlyNevada, ABB, Emerson Ovation, Honeywell DCS, Rockwell ICS Triplex, FOXBORO, Schneider PLC, GE Fanuc, Motorola, HIMA, TRICONEX, Prosoft etc. Various kinds of imported industrial parts

NI CFP-DI-304 Digital input module block

• DNP PORT: Select the appropriate PQMII port to be used for DNP protocol. The COM2 selection is only available if T1 or T20 option is installed in the PQMII. Each port is configured as shown in 5.2.4: Serial Ports. • DNP SLAVE ADDRESS: Enter a unique address from 0 to 255 for this particular PQMII. The address selected is applied to the PQMII port currently assigned to communicate using the DNP protocol. Although addresses do not have to be sequential, no two PQMIIs that are daisy chained together can have the same address or there will be conflicts resulting in errors. Generally each PQMII added to the link will use the next higher address. • DNP TURNAROUND TIME: The turnaround time is useful in applications where the RS485 converter without RTS or DTR switching is being employed. A typical value for the delay is 30 ms to allow the transmitter to drop in the RS485 converter.

• SET TIME/DATE: These messages are used to set the time and date for the PQMII software clock. The PQMII software clock is retained for power interruptions of approximately thirty days. A Clock Not Set alarm can be enabled so that an alarm will occur on the loss of clock data. The time and date are used for all time-stamped data. If the clock has not been set, a “?” will appear on the right-hand side of the displayed time for all timestamped data. Follow the steps shown below to set the new time and date.

EXTRACT FUNDAMENTAL

The PQMII can be programmed to calculate all metering quantities using true RMS values or the fundamental component of the sampled data. When this setpoint is set to “Disable”, the PQMII will include all harmonic content, up to the 32nd harmonic, when making metering calculations. When this setpoint is set to “Enable”, the PQMII will extract the fundamental contribution of the sampled data only and use this contribution to calculate all metering quantities. Many utilities base their metering upon fundamental, or displacement, values. Using the fundamental contribution allows one to compare the quantities measured by the PQMII with the local utility meter. • CURRENT DEMAND TYPE: Three current demand calculation methods are available: thermal exponential, block interval, and rolling interval (see the Demand Calculation Methods table below). The current demand for each phase and neutral is calculated individually. • CURRENT DEMAND TIME INTERVAL: Enter the time period over which the current demand calculation is to be performed.• POWER DEMAND TYPE: Three real/reactive/apparent power demand calculation methods are available: thermal exponential, block interval, and rolling interval (see the Demand Calculation Methods table below). The three phase real/reactive/apparent power demand is calculated. • POWER DEMAND TIME INTERVAL: Enter the time period over which the power demand calculation is to be performed.