Home > Product > Gas turbine system > GE VMIVME-1181 I/O module of gas turbine

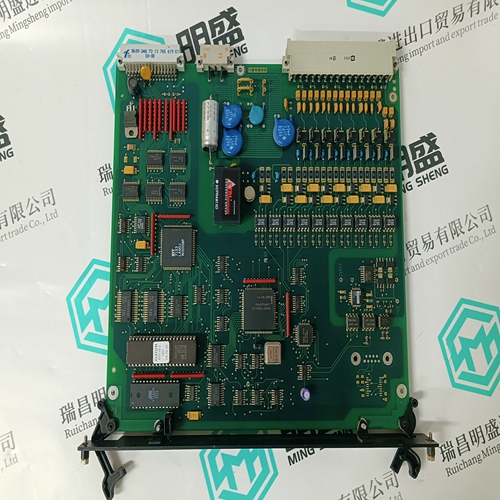

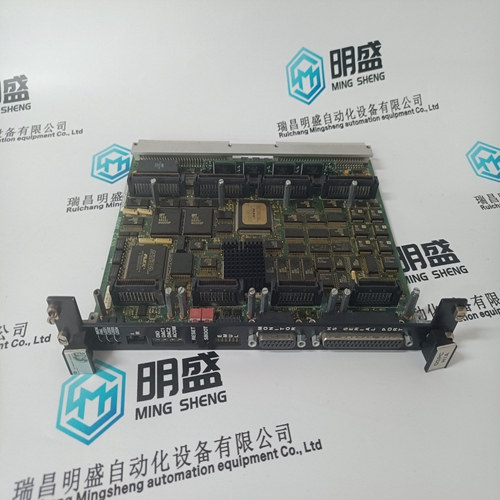

GE VMIVME-1181 I/O module of gas turbine

- Product ID: VMIVME-1181

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:GEVMIVME-1181I/O module of gas turbine

- Get the latest price:Click to consult

GE VMIVME-1181 I/O module of gas turbine

Setting Method There are three ways to set cubic interference areas, as described in the following: Number Input of Cube Coordinates Enter the maximum and minimum values for the cube coodinates.Move the manipulator at the maximum and minimum value positions of the cube corner using the axis keys.Number Input of the Side of Cube and Teaching Center After entering the lengths of the three faces of the cube (axial length) using the number keys, move the manipulator to the center point of the cube using the axis keys.

The axis interference area is a function that judges the current position of the each axis and outputs a signal. Once the maximum and minimum values have been set at the plus and minus sides of the axis to define the operating range, a signal indicating whether the current position of the axis is inside or outside this range is output. (ON: inside, OFF: outside)

Setting Operation

*1 The cubic interference area display is shown.

*2 Select the desired interference signal number using the page key or by number input. The method for number input is as follows: Move cursor to “INTERFERENCE SIG” and press [ENTER] to display the number input line. Input desired signal number and press [ENTER].

*3 ”AXIS INTERFERENCE” and “CUBIC INTERFERENCE” are displayed alternately every time [SELECT] is pressed. Select “AXIS INTERFERENCE”.

*4 The selection dialog is displayed. Select desired control group.

*5 Each time [SELECT] is pressed, “COMMAND POSITION” and “FEEDBACK POSITION” alternate.

Setting Axis Data by Moving Manipulator Using the Axis Key

The Operation Origin Point is a reference point for manipulator operations. It prevents interference with peripheral devices by ensuring that the manipulator is always within a set range as a precondition for operations such as starting the line. The manipulator can be moved to the set operation origin point by operation from the programming pendant, or by signal input from an external device. When the manipulator is in the vicinity of the operation origin point, the operation origin point signal turns ON.

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.