Home > Product > Gas turbine system > GE VMIVME-1330 I/O module of gas turbine

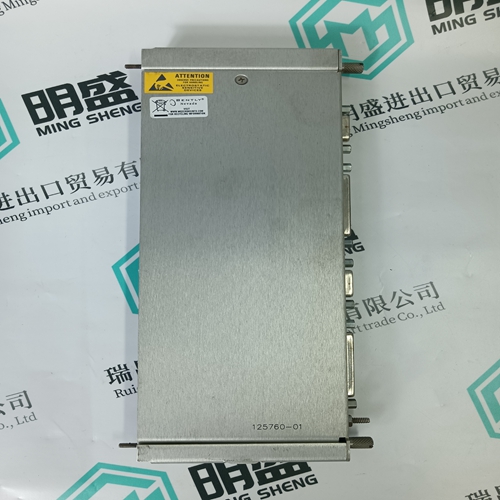

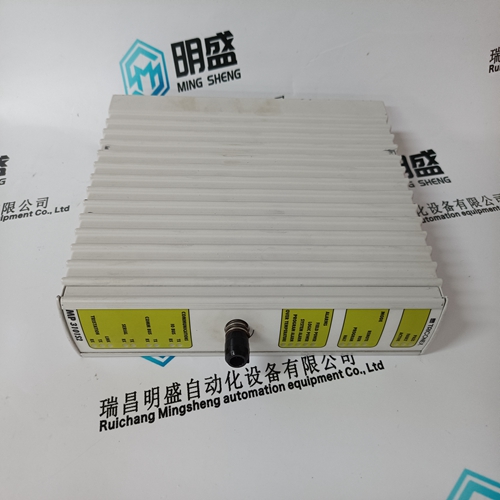

GE VMIVME-1330 I/O module of gas turbine

- Product ID: VMIVME-1330

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:GEVMIVME-1330I/O module of gas turbine

- Get the latest price:Click to consult

GE VMIVME-1330 I/O module of gas turbine

Tool Calibration To ensure that the manipulator can perform interpolation operations such as linear and circular interpolation correctly, accurate dimensional information on tools such as torches, tools, and guns must be registered and the position of the tool center point must be defined. Tool calibration is a function that enables this dimensional information to be registered easily and accurately. When this function is used, the tool center point is automatically calculated and registered in the tool file. What is registered in tool calibration is the coordinates of the tool center point in the flange coordinates.

Teaching

In order to perform tool calibration, five different poses (TC1 to 5) must be taught with the tool center point as the reference point. The tool dimensions are automatically calculated on the basis of these five points.Each pose must be arbitrary. Accuracy may decrease when pose setting is rotated in a constant direction.There are 24 tool files numbered 0 to 23. In a basic system with one manipulator and one tool, the tool file for tool No.0 is used. If there is more than one tool, for example when using a multihand, use the tool numbers in the order 0, 1, 2

Select the robot to calibrate

(When the robot has already been selected or there is only one of robot, this operation should not be performed.) Select “**” in the tool calibration setting display and select the robot in the displayed selection dialog.Taught position is registered. Repeat *4~*5 operation to teach TC1 to TC5. z indicates that teaching is completed and { indicates that it is not completed.To check the taught positions, call up the required display among TC1 to TC5 and press [FWD]. The manipulator moves to the set position. If there is a difference between the current position of the manipulator and the displayed position data, “TC “ next to “POSITION” in the display flashes.

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.