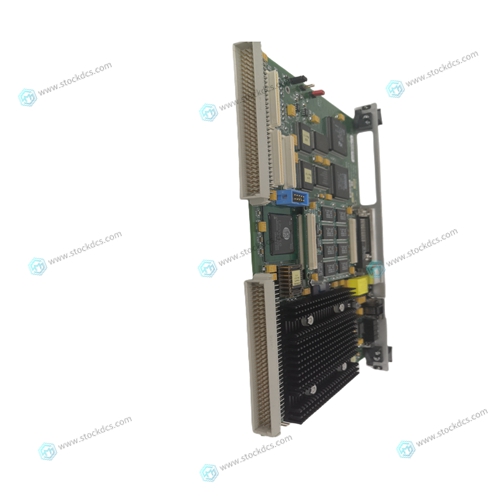

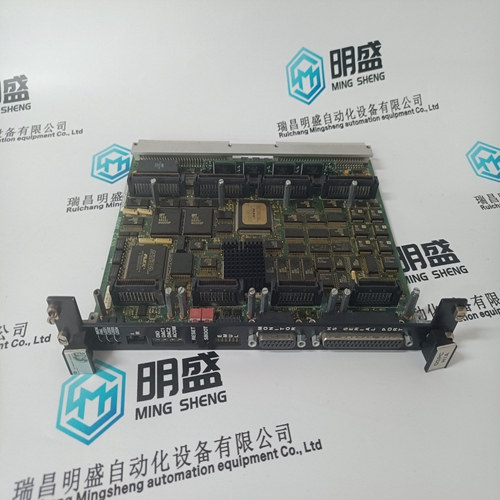

Home > Product > Gas turbine system > GE VMIVME-2232 Gas turbine control module

GE VMIVME-2232 Gas turbine control module

- Product ID: VMIVME-2232

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:GEVMIVME-2232Gas turbine control module

- Get the latest price:Click to consult

GE VMIVME-2232 Gas turbine control module

S-head payload Set the mass and the center of gravity position roughly when the equipment such as transformer is installed at the S-head. It is not necessary to set these value when there is no installed load at the S-head. WEIGHT (Unit:kg) The weight of the installed load is set. Set a little large value though it does not care by a rough value. (Rase to a unit in each 0.5 to 1kg) X (From S-Axis), Y (From S-Axis) (unit: mm) The center of gravity position of the installed load is set by the distance in the direction of X and the direction of Y from S axis center here. It does not care by a rough value. The direction of X and Y applies to the robot coordinates. The value is set by a negative number when the position is in “-” direction.

U-arm payload

Set the weight and the center of gravity position roughly when the equipment such as the wire supplying motors is installed on U arm. A standard value is set when shipping from the factory. Set the weight in “0” if there is no installing equipment on U arm. WEIGHT (Unit:kg) The weight of the installing load is set here. Set a little large value though it does not care by a rough value. (Rase to a unit in each 0.5 to 1kg)The center of gravity position of the load installed is set here. It does not care by a rough value. X (From U-Axis) is horizontal distance from U axis rotation center to the center of gravity position of the load. Set negative number when there is mass side in the back from U axis rotation center.

Tool Load Information Setting

• Set the tool load information correctly. The speed reducer longevity might decrease or the alarm might occur when the tool load information is not set correctly. • Confirm the operation path of robot of each job which uses the tool file after the tool load information is changed. Set the tool load information basically before teaching the job after the tool is installed. Confirm the operation path of each job which uses the tool file when the tool load information is changed after teaching, unavoidably. Injury or damage to machinery may result by collision between tool and jig because the operation path might be changed slightly when the tool load information is changed.

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.