Home > Product > Gas turbine system > GE VMIVME-6005 Gas turbine I/O card

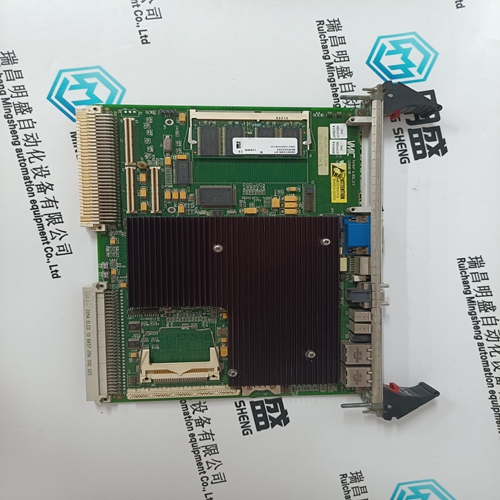

GE VMIVME-6005 Gas turbine I/O card

- Product ID: VMIVME-6005

- Brand: GE

- Place of origin: The United States

- Goods status: new/used

- Delivery date: stock

- The quality assurance period: 365 days

- Phone/WhatsApp/WeChat:+86 15270269218

- Email:xiamen2018@foxmail.com

- Tags:GEVMIVME-6005Gas turbine I/O card

- Get the latest price:Click to consult

GE VMIVME-6005 Gas turbine I/O card

Only the rising edge of the servo ON signal is valid. This signal turns ON the manipulator servo power supply. The set and reset timings are shown in the following.Only the rising edge of the external start signal is valid. This signal starts the manipulator. Reset this signal with the interlock configuration that determines if operation can start and with the playback (RUNNING) signal confirming that the robot has actually started moving.When the shock sensor input signal is used, the stopping method of the robot can be specified. The stopping methods are hold stop and servo power supply off. Selection of the stopping method is set in the display of the programing

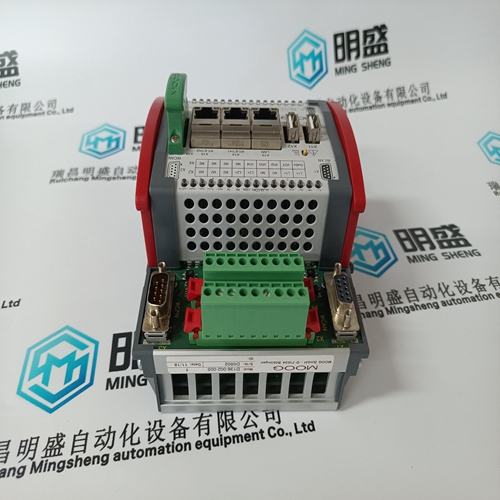

Power-on Circuit Board

The power-on circuit board is controlled by the servo control circuit board (JASP-WRCA01 ). The main functions are as follows: • Specific I/O circuit, for instance, servo power supply contactor I/O circuit and emergency stop circuit • Brake power supply circuit and its output • Overrun(OT) shock sensor(SHOCK) and lamp light power supply output to robot Connection of Shock Sensor Remove SHOCK- and +24VU from XIU-CN25 (Dynamic Connector) , and connect the shock sensor signal SHOCK- to the robot.

Connection of External Power Supply for I/O

At factory setting, the internal power supply for I/O is used. If the external power supply for I/O is used, connect it with following procedure. 1. Remove the wire connected between CN26-7 to -9 and CN26-8 to -10 of the I/O contactor unit: JZNC-XIU01 . 2. Connect +24V of the external power supply to CN26-7 and 0V to CN26-8 of the I/O contactor unit: JZNC-XIU01 .

• The internal power supply of 24V of about 1A of XRC can be used for I/O. Use external 24V power supply for higher currents and to isolate the circuit inside and outside the XRC. • The I/O power supply (+24 VU, 024 VU) has 3A fuses (FU3,FU4). • Install the external power supply outside the XRC to avoid electric noise problems. • When the internal power supply is selected, do not connect the line of the external power supply to the +24VU and 0VU terminals. The unit may malfunction if the external power supply is also connected.

[Main Products]

Main products: PLC and DCS system spare parts modules of world famous brands

①Allen-Bradley 1756、1746、1747、1771、1785

②Schneider 140 Series PLC module

③General electric GE IC693 IC697 IC698 Series PLC module

DS200 DS3800 DS215 IS200 IS215 IS220 Series gas turbine module

VMIVME Control module of series

④Bently:3500 series cards 3500/22M、3500/15、3500/92 And other products

⑤ICS TRIPLEX

⑥ABB Robots. FANUC Robots、YASKAWA Robots、KUKA Robots、Mitsubishi Robots、OTC Robots、Panasonic Robots、MOTOMAN Robots。

⑦EMERSON:Spare parts for OVATION system, WDPF system and MAX1000 system.

⑧ Invensys Foxboro: I/A Series system, FBM (field input/output module) sequential control, ladder logic control, accident recall processing, digital analog conversion, input/output signal processing, data communication and processing, etc. Invensys Triconex: redundant fault-tolerant control system, Zui modern fault-tolerant controller based on triple module redundancy (TMR) structure.

⑨Woodward:505 series governor 9907-164 And other products

⑩Bosch Rexroth:Indramat,I/O module,PLC CPU,Motors, drives and other products.

◆Motorola:MVME 162、MVME 167、MVME1772、MVME177and other products.